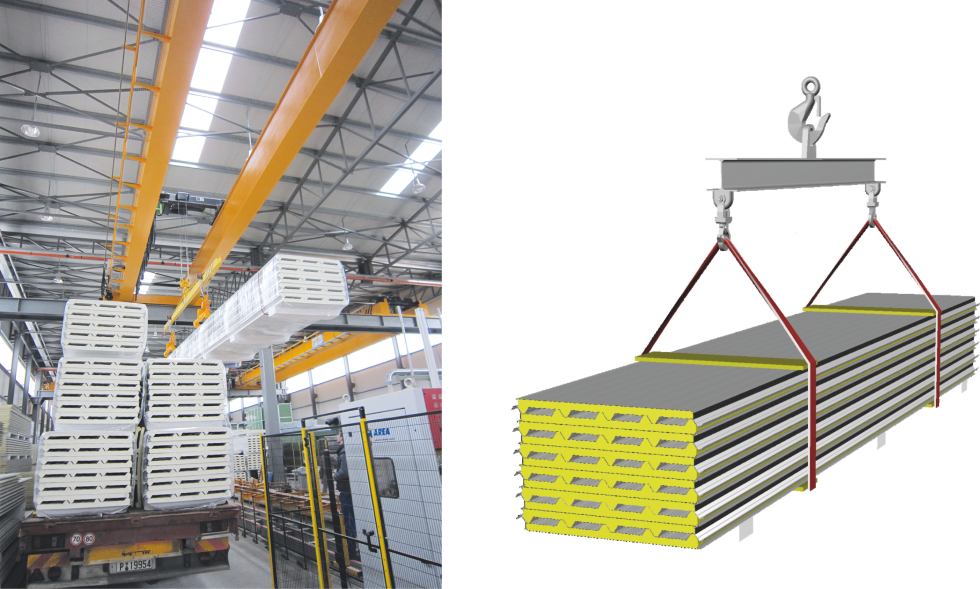

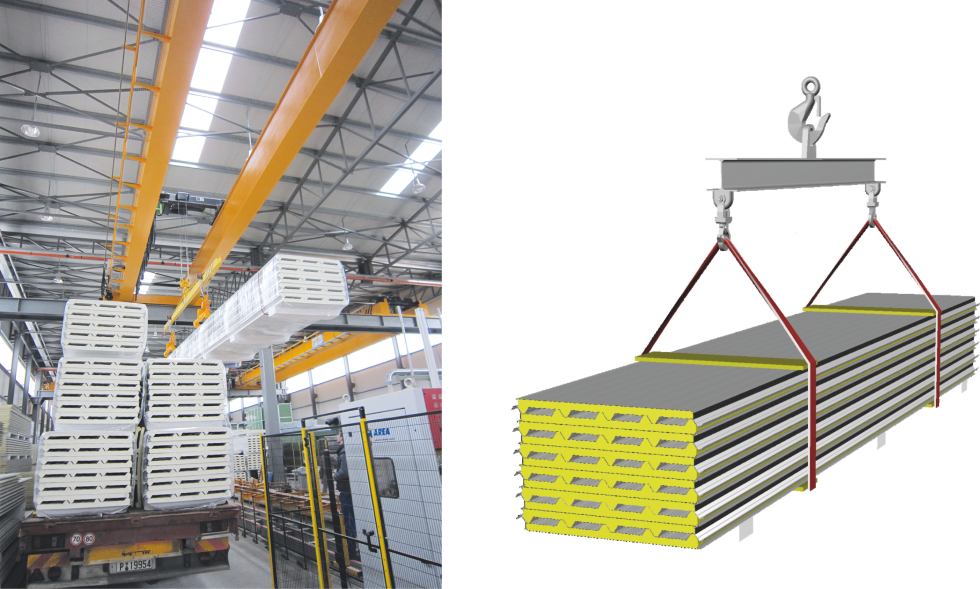

Long packs should be unloaded either with the use of spreader beam or long belts. Pre-painted sheets should not be dragged.

CODE / ΚΩΔ.: PF-mLC

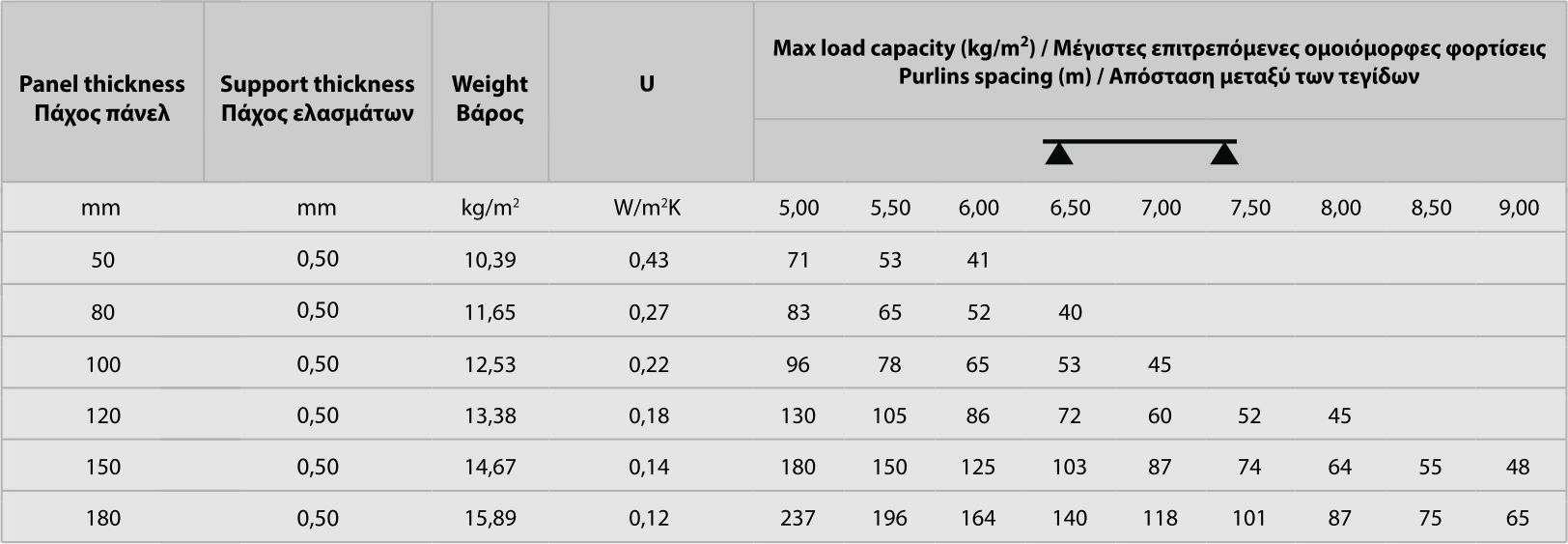

Table of allowed loads for single span loading

Technical specifications

Domolam insulating panels are produced according to the standard EN 14509:2013 and have CE marking.

THE INSULATION:

The polyurethane foam PUR is chemically neutral, non toxic and it is produced with environmental friendly technology with the use of pentane (CFC, HCFC free).

Domolam insulating panels are produced with PUR foam with reaction to fire Cs3d0 or in altenatively they are produced with polyisocyanurate foam PIR High Index, with reaction to fire Bs1d0 according to EN 13501-1, ΕΝ 11925-2 and EN 13823.The wall panels (vertical partition - EN 1364-1) have fire resistance EI30: E 60 and the roof panels (horizontal partition -EN 1365-2) have fire resistance REI30: RE 60 for the thickness 100mm,according to EN 13501-2.

Both PUR and PIR High Index foam contain a high percentage of closed cells >95% (waterproof/mould resistant) providing perfect adhesion to the supports.

Thermal conductivity factor λ=0,0215 W/mK and its average density is 40-42 Kg/m3 according to EN 13165.

Average comression strength 120 KPa.

Average adhession strength 140 KPa.

Average shear strength 100 KPa.

THE METALLIC SUPPORTS ARE:

-Pre-painted steel, in compliance with the EN 10169 standard, on hot dipped galvanized or aluzinc steel with yield strength 250-280 N/mm2 according to EN 10346 and EN 10143.

-Plastified anti-bacterial coated steel special for cold rooms and hygienic applications.

-Pre-painted, smooth or embossed aluminum, copper and stainless steel on demand.

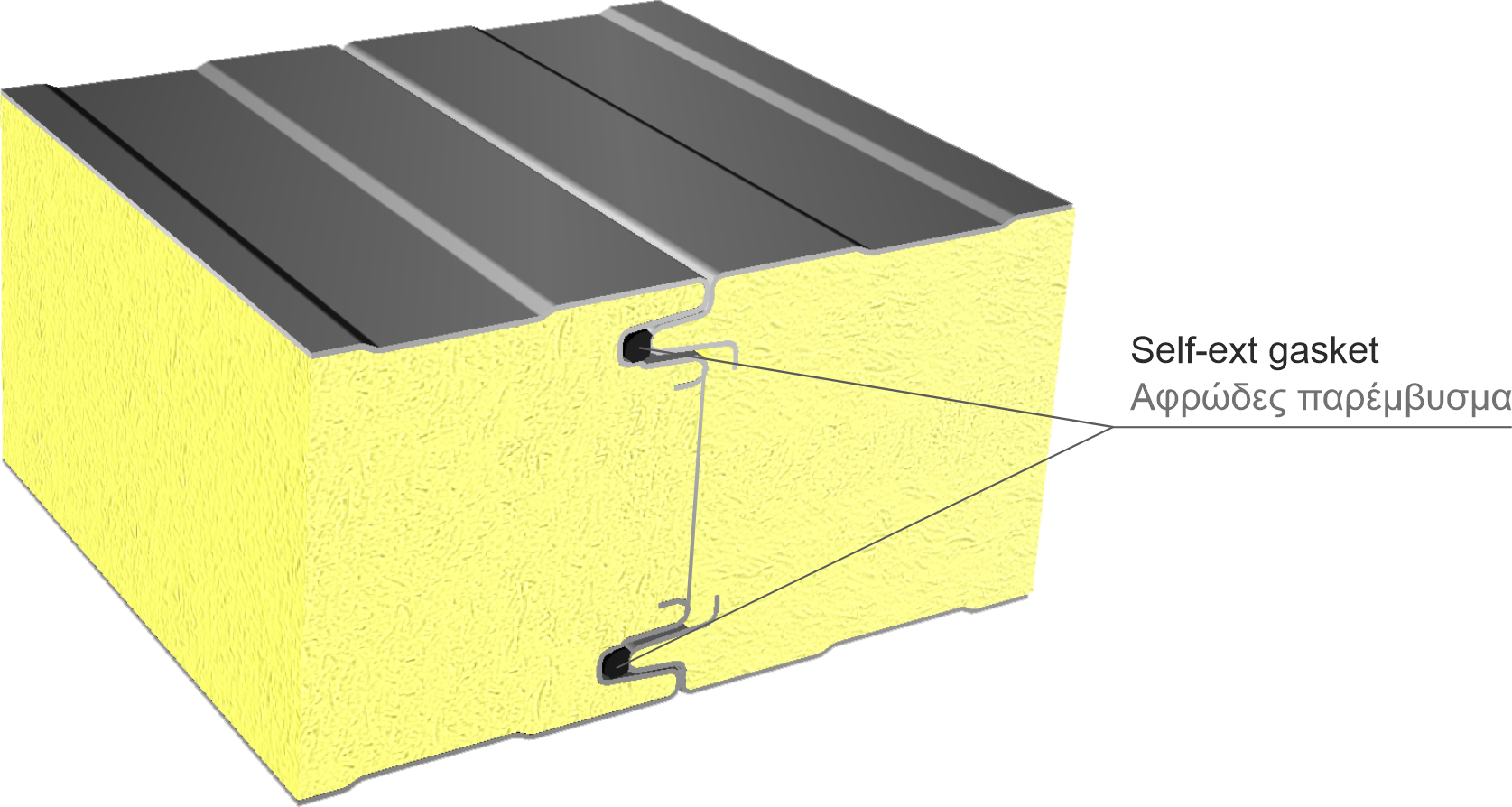

JOINT TIGHTNESS:

Water Permeability: Class A, EN 12865

Air Permeability: 0,14m3/m2/h at 50 Pa, EN 12114

DIMENSIONS TOLERANCES according to Annex D of ΕΝ 14509:

| Corrugation height | ±1mm |

| Pitch of profile | ±2mm |

| Panel length | ±10mm |

| Panel thickness | ±2% του πάχους |

| Squareness | 0,6% ωφέλιμου πλάτους |

| Longitudinal bowing | 2 mm/m - 10 mm |

| Camber | ≤1% του πλάτους |

| Flatness | ≤-1,5mm στα 700mm |

| Edge waveness | ±2mm στα 500mm μήκους |

| Useful width | ±2mm |

| length (mm) | small | big | weight (kg/m) | weight (kg/m2) | quantity | price per unit (€) | value (€) | Comments |