- Characteristics

- Instructions

- Applications

- Certificates

The raw materials used meet high quality and technical standards:

• Cold rolled steel sheets (CR): commercial quality and drawing quality DC01 (according to the standard EN 10130:2006) or ST12 (according to the standard DIN 1623/1624) and quality DC01EK (according to the standard EN 10209:2013) suitable for enamelling.

• Hot rolled steel sheets (ÇR): pickled or not, flat, checkered (according to the standards EN 10025:2004 and ΕΝ 10029:2010).

• Hot-dip zinc coated coils (HDG): DX51D+Z, S280GD+Z και S320GD+Z according to the standard EN 10346:2015. Dimension tolerances according to the standard EN 10143:2006. Coating Ζ275-150.

• Aluminum coated coils: Aluzinc AZ-DX51D+AZ150 (45%Zn, 55%Al) according to the standard ΕΝ 10346:2015.

• Zinc-aluminium-magnesium alloy coated coils: Magnelis ZM -DX51D+ZM90 (93,5% Zn,3,5%Al, 3%Mg) according to the standard ΕΝ 10346:2015.

• Pre-painted galvanized coils: according to the standard EN 10169:2010 + Α1:2012 with standard polyester 25μ paint in 30 colors. Silicon polyester paints, PVDF and other colors upon request.

• Upon request the process of stainless steel, titanzinc, copper and aluminium is possible.

• Hot rolled steel sheets (ÇR): pickled or not, flat, checkered (according to the standards EN 10025:2004 and ΕΝ 10029:2010).

• Hot-dip zinc coated coils (HDG): DX51D+Z, S280GD+Z και S320GD+Z according to the standard EN 10346:2015. Dimension tolerances according to the standard EN 10143:2006. Coating Ζ275-150.

• Aluminum coated coils: Aluzinc AZ-DX51D+AZ150 (45%Zn, 55%Al) according to the standard ΕΝ 10346:2015.

• Zinc-aluminium-magnesium alloy coated coils: Magnelis ZM -DX51D+ZM90 (93,5% Zn,3,5%Al, 3%Mg) according to the standard ΕΝ 10346:2015.

• Pre-painted galvanized coils: according to the standard EN 10169:2010 + Α1:2012 with standard polyester 25μ paint in 30 colors. Silicon polyester paints, PVDF and other colors upon request.

• Upon request the process of stainless steel, titanzinc, copper and aluminium is possible.

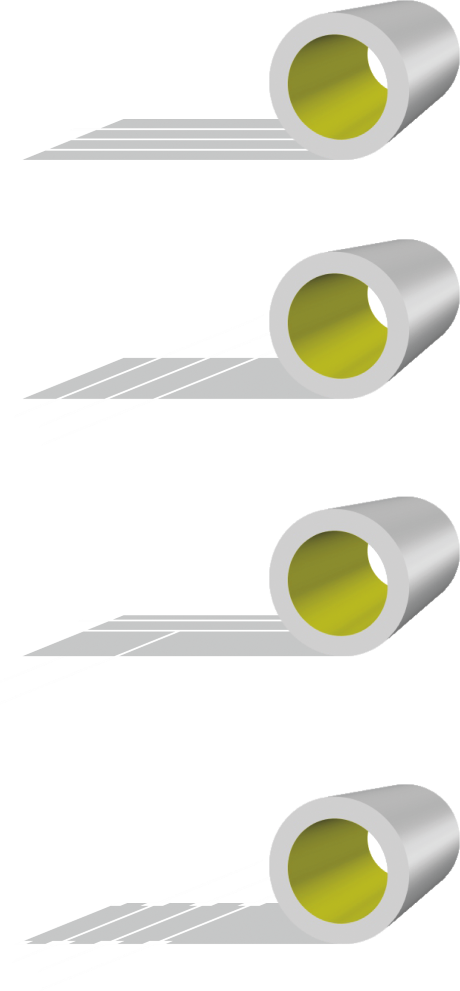

Production capability

Storage

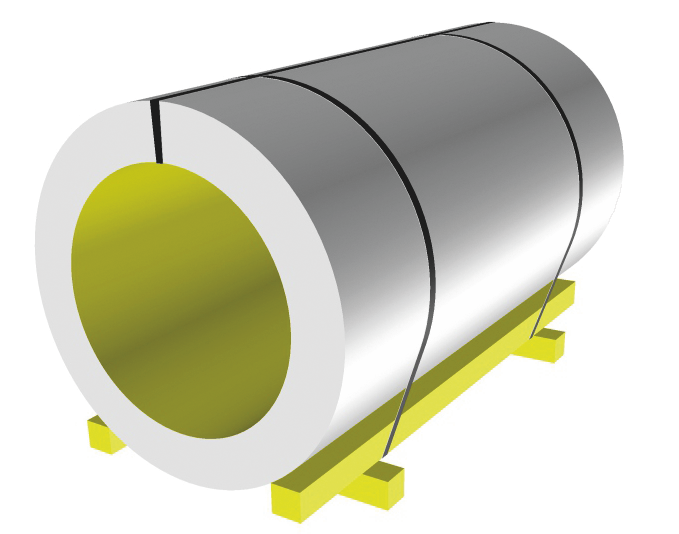

The materials are delivered on wooden planks or palettes, fastened with the necessary steel straps, bare, with paper or metal package, depending on the customer’s financial and quality requirements.

CODE / ΚΩΔ.: P01

CODE / ΚΩΔ.: P02

| length (mm) | small | big | weight (kg/m) | weight (kg/m2) | quantity | price per unit (€) | value (€) | Comments |

Metal sheet coils

At the most contemporary slitting and cutting lines with continuous slitting and cutting into length processes, flat metal sheets are produced with particular characteristics, great precision and strict quality requirements. The products are available in coils, strips, plates and pieces with processed corners or not, in standard (commercial) or customized dimensions and quantities that meet the customer’s true needs, promptly and at the most competitive prices.

The services of the metal sheet service center SERVILAM include study, design and production of personalized solutions. All the customer’s production problems are faced in confidence, assiduity and scientific approach and matters such as wastage handling, high stocking and quality matters are eliminated in the best way. The processing of customer’s material in subcontracting basis is also possible.