- Characteristics

- Instructions

- Applications

- Certificates

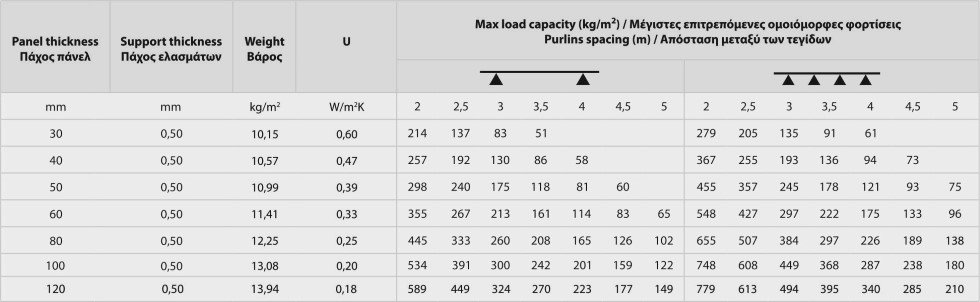

Technical specifications

Domolam insulating panels are produced according to the standard EN 14509:2013 and have CE marking.

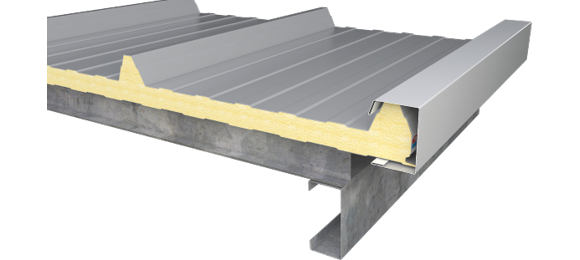

THE INSULATION:

The polyurethane foam PUR is chemically neutral, non toxic and it is produced with environmental friendly technology with the use of pentane (CFC, HCFC free).

Domolam insulating panels are produced with PUR foam with reaction to fire Cs3d0 or in altenatively they are produced with polyisocyanurate foam PIR High Index, with reaction to fire Bs1d0 according to EN 13501-1, ΕΝ 11925-2 and EN 13823.The wall panels (vertical partition - EN 1364-1) have fire resistance EI30: E 60 and the roof panels (horizontal partition -EN 1365-2) have fire resistance REI30: RE 60 for the thickness 100mm,according to EN 13501-2.

Domolam roof panels are classified as BROOF(t1) according to the standard CEN / TS 1187:2013.

Both PUR and PIR High Index foam contain a high percentage of closed cells >95% (waterproof/mould resistant) providing perfect adhesion to the supports.

Thermal conductivity factor λ=0,0215 W/mK and its average density is 40-42 Kg/m3 according to EN 13165.

Average comression strength 120 KPa.

Average adhession strength 140 KPa.

Average shear strength 100 KPa.

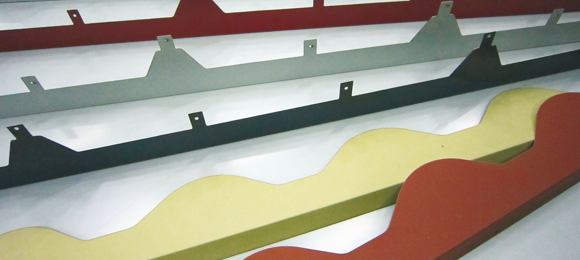

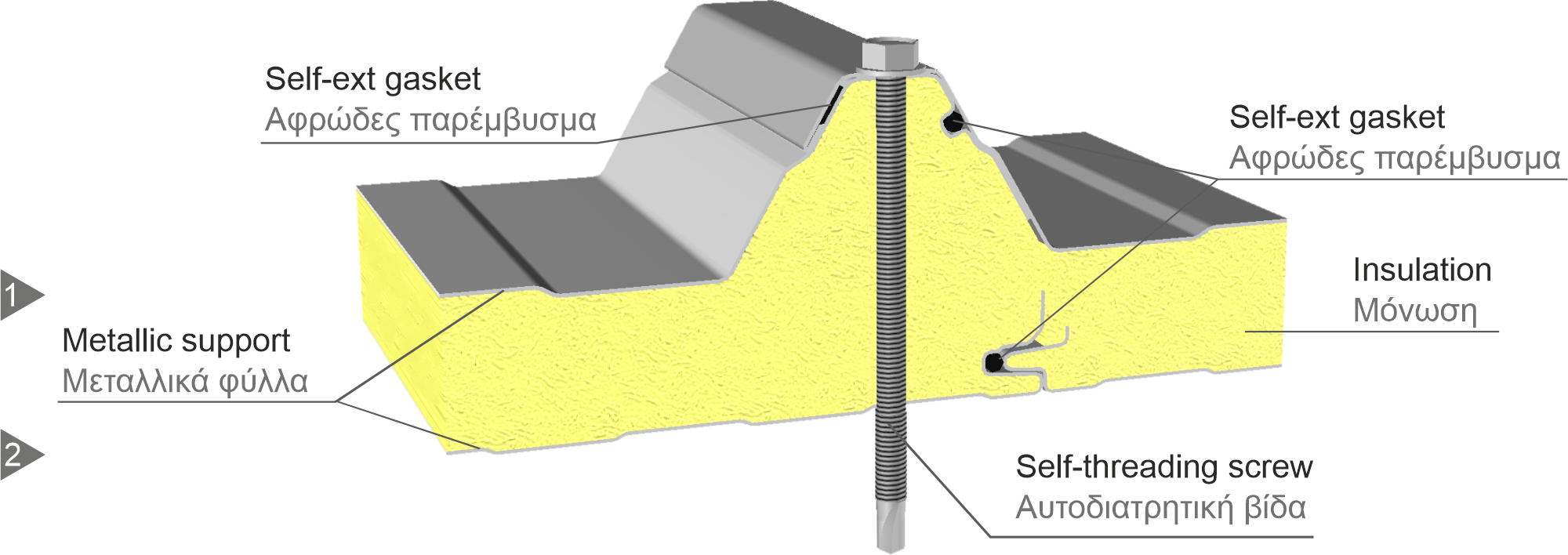

THE METALLIC SUPPORTS ARE:

-Pre-painted steel, in compliance with the EN 10169 standard, on hot dipped galvanized or aluzinc steel with yield strength 250-280 N/mm2 according to EN 10346 and EN 10143.

-Plastified anti-bacterial coated steel special for cold rooms and hygienic applications.

-Pre-painted, smooth or embossed aluminum, copper and stainless steel on demand.

JOINT TIGHTNESS:

Water Permeability: Class A, EN 12865

Air Permeability: 0,14m3/m2/h at 50 Pa, EN 12114

DIMENSIONS TOLERANCES according to Annex D of ΕΝ 14509:

| Corrugation height | ±1mm |

| Pitch of profile | ±2mm |

| Panel length | ±10mm |

| Panel thickness | ±2% of thickness |

| Squareness | 0,6% useful width |

| Longitudinal bowing | 2 mm/m - 10 mm |

| Camber | ≤1% of width |

| Flatness | ≤-1,5mm over 700mm |

| Edge waveness | ±2mm over 500mm of length |

| Useful width | ±2mm |

Remarks

Slight leaking of foam from the joints, small foam vacuum or slight omissions and irregularities in the position of the gasket are acceptable, as long as the functional character of the panel is not compromised.

OVERLAPPING BY LENGTH:

For panels overlapped by length, the cleared part position Left or Right should be defined, according to the assembly direction.

LEFT RIGHT

RIGHT

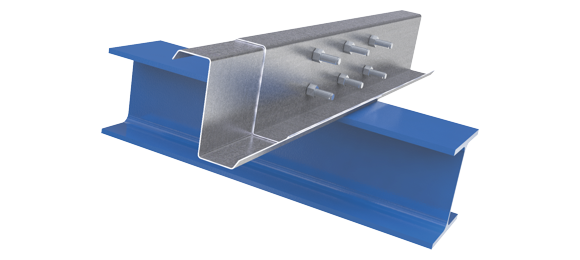

Fastening should stop when the sheet starts deforming under the screw, to ensure the best aesthetic and static results.

PROJECT 19

RAL 6005

PROJECT 9

RAL 6005

PROJECT 6

RAL 9002

PROJECT 18

RAL 9002

PROJECT 18

RAL 9002

PROJECT 18

RAL 9002

PROJECT 28

RAL 9002

PROJECT 28

RAL 9002

PROJECT 33

RAL 3003

PROJECT 35

RAL 3003

PROJECT 36

RAL 9002

PROJECT 21

RAL 3003

PROJECT 44

RAL 5010

PROJECT 56

RAL 9002

| length (mm) | small | big | weight (kg/m) | weight (kg/m2) | quantity | price per unit (€) | value (€) | Comments |

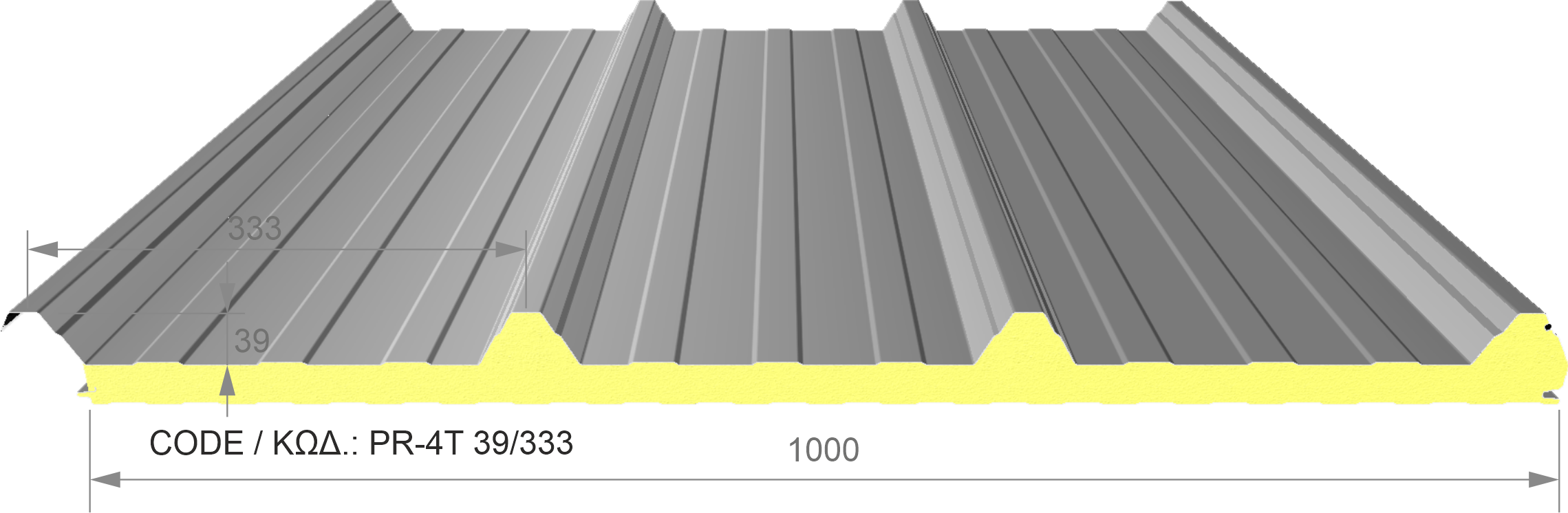

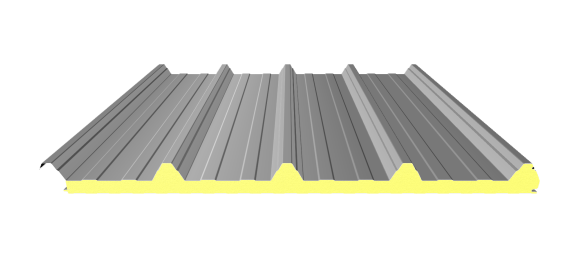

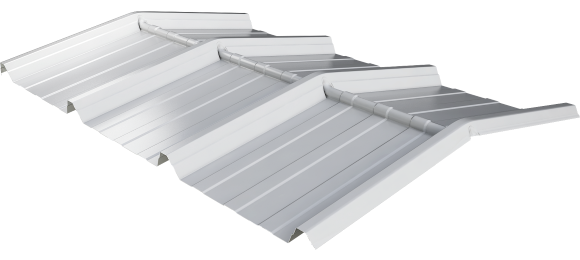

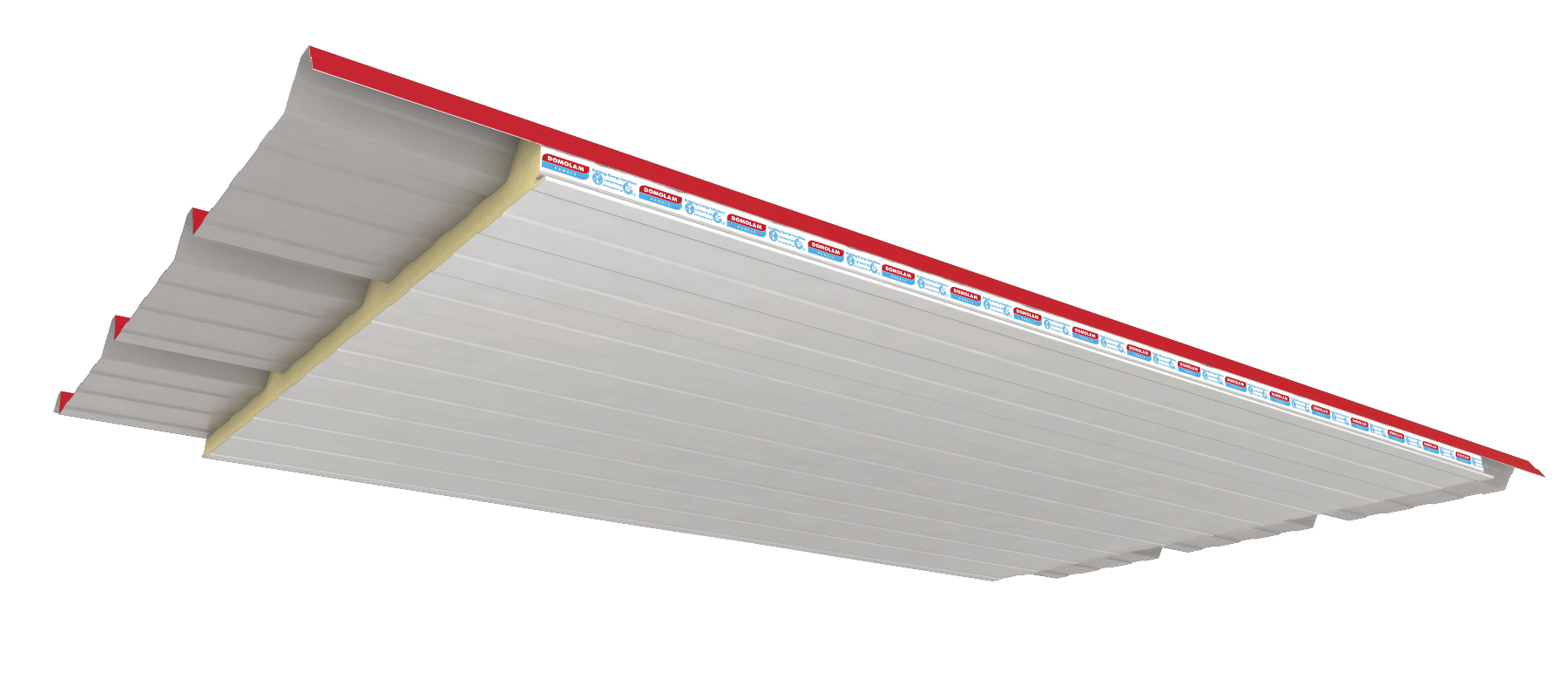

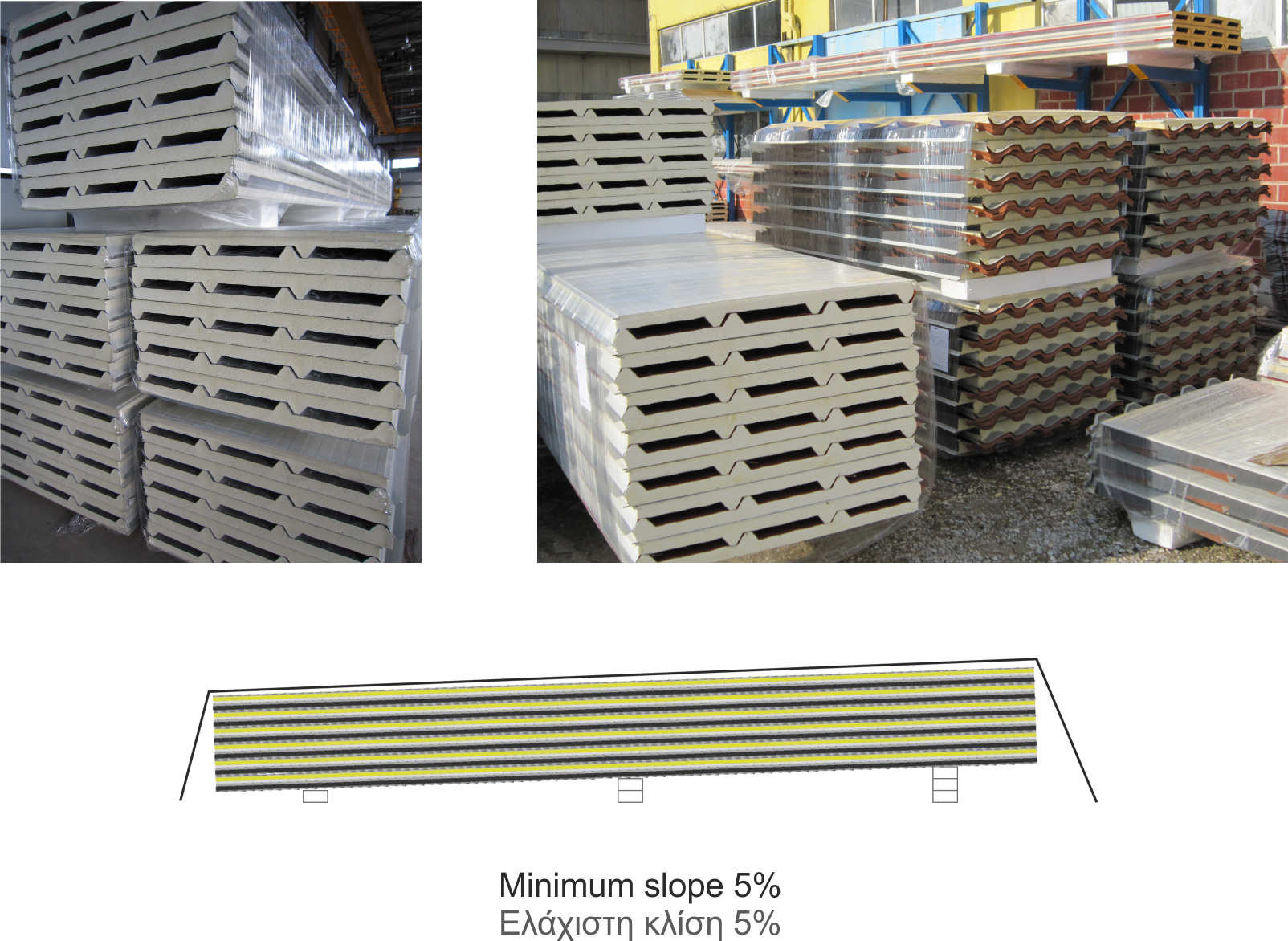

Roof panel with 4 ribs PR-4T 39/333

Domolam roof panels points of excellence

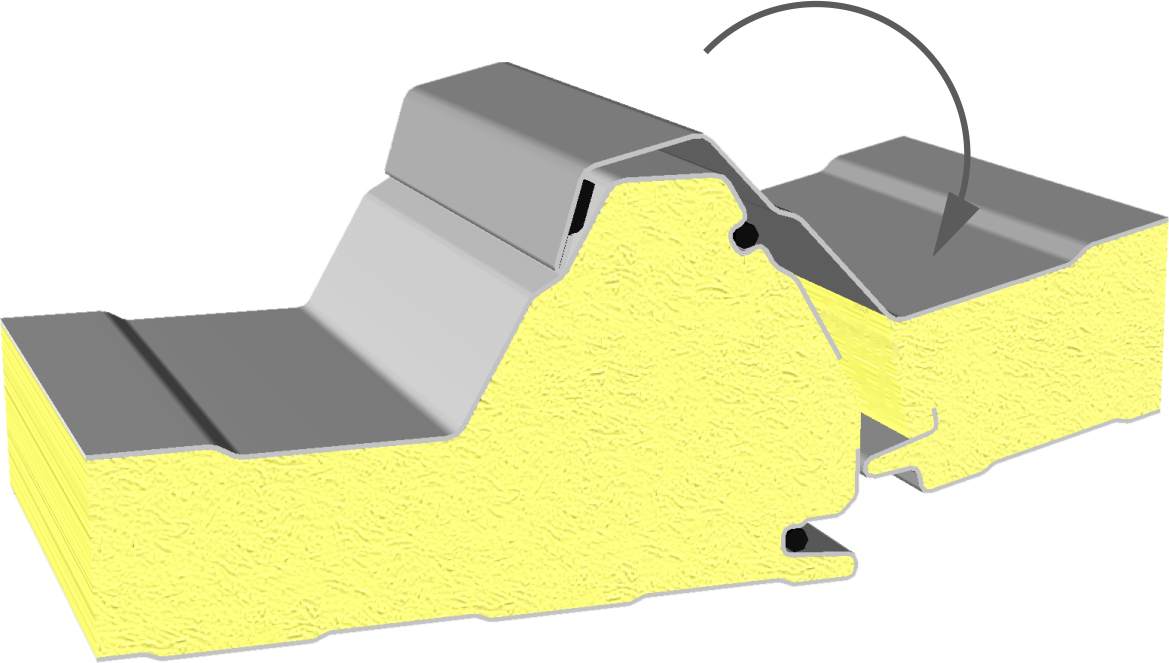

1. The innovative joints details ensure absolute water and air tightness.

2. Produced with special ribs at the sides of the trapezoidal formations for increasing the bearing capacity of them.

3. Combined according to their type with innovating photovoltaic cells in adhesive membrane.

4. Disposed also specially formed for right or left overlapping by length.