- Characteristics

- Instructions

- Applications

- Certificates

Industrial gutters of fixed section

Installation

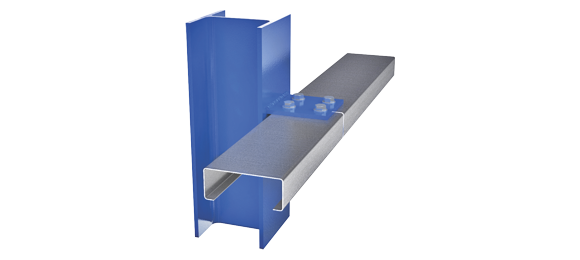

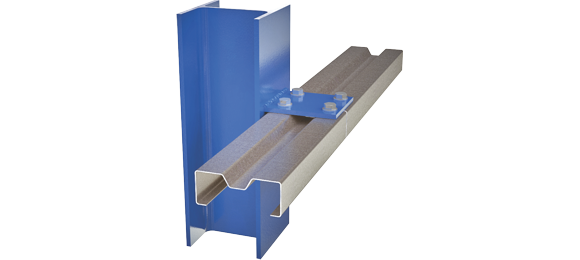

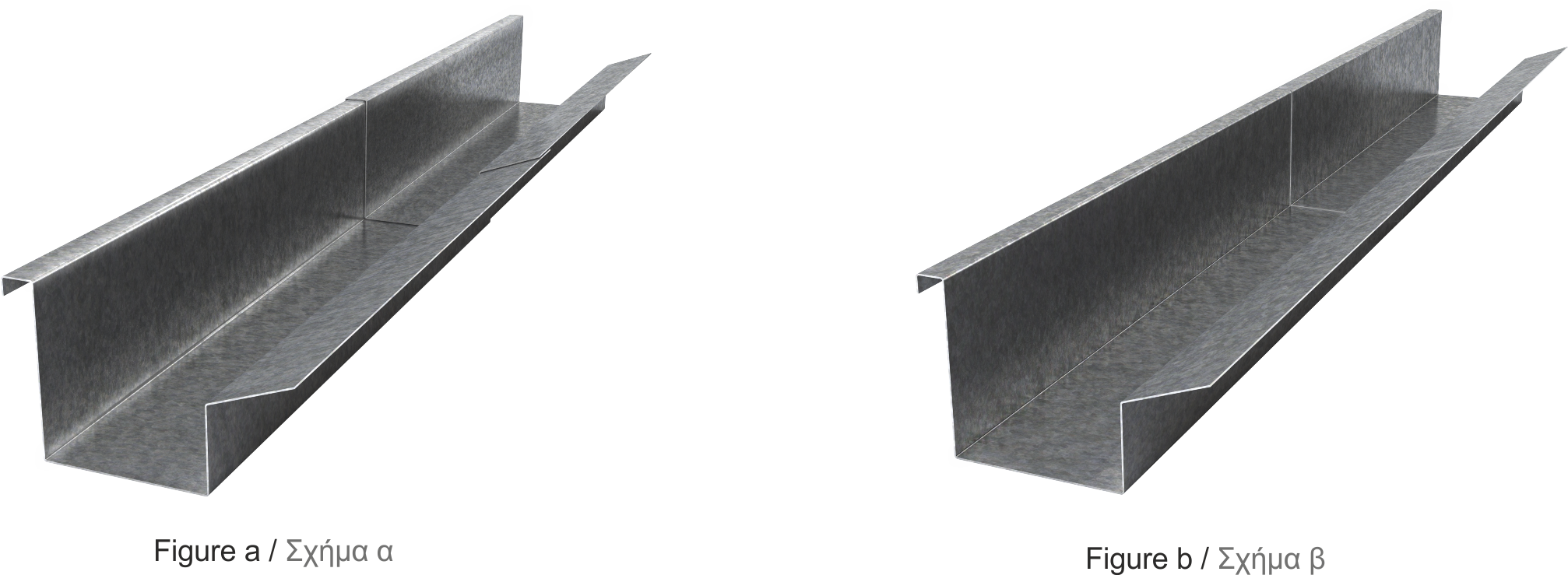

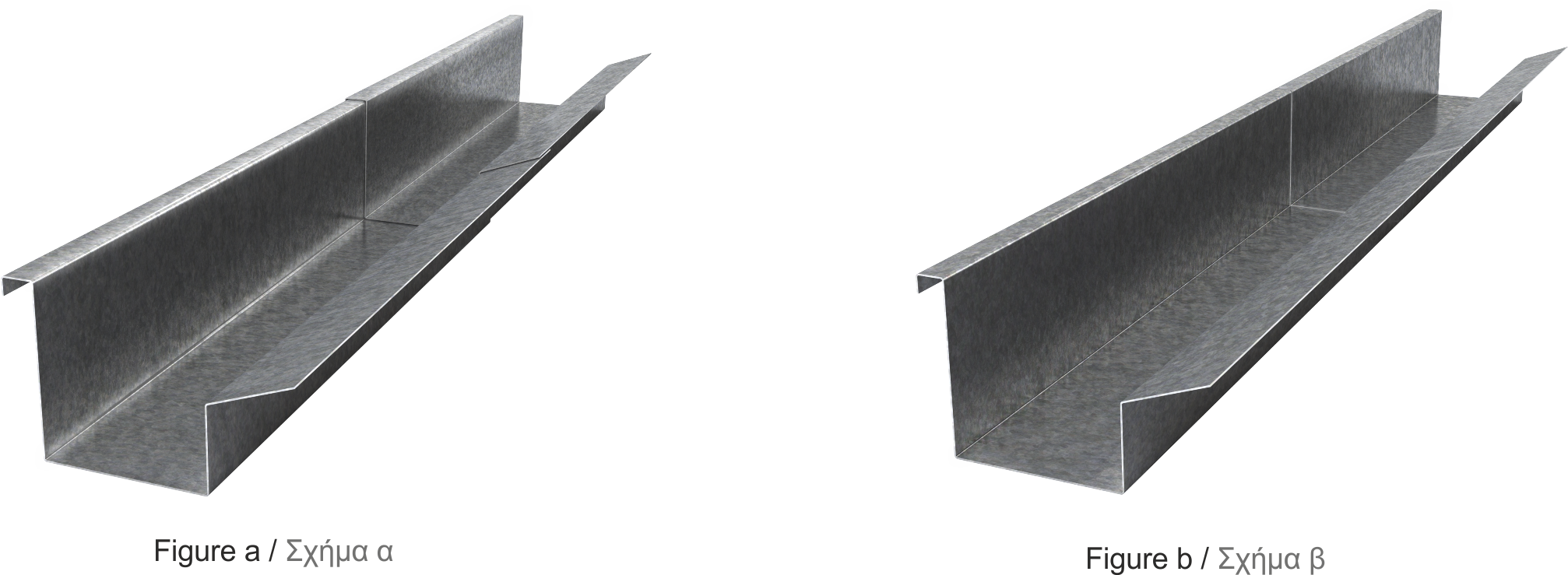

Gutters are connected with overlapping (figure a & c) or face to face (figure b & d).

| external plate | width | length | packaging | quantity | Price | ||||||||||||

| material | thickness | spread | unit | length (mm) | small | big | weight (kg/m) | weight (kg/m2) | quantity | price per unit (€) | value (€) | Comments | |||||

| Successfully added to cart Quantity is missing Length is missing | GUTTERS IGF | ISOLAM | 1000 | kg | 1 | 20 | 0.7 | ||||||||||

Industrial gutters of fixed section

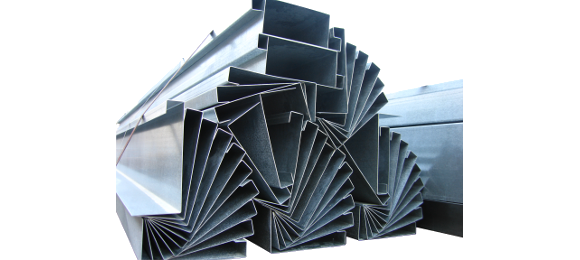

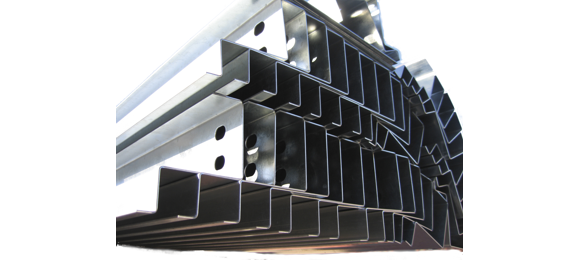

Our company, with the operation of the most contemporary bending center, produces industrial gutters in standard width 500, 625, 750, 1000, 1250 and 1500mm or in customized width.

They are produced in two types:

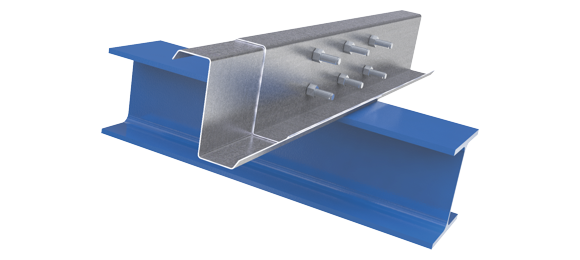

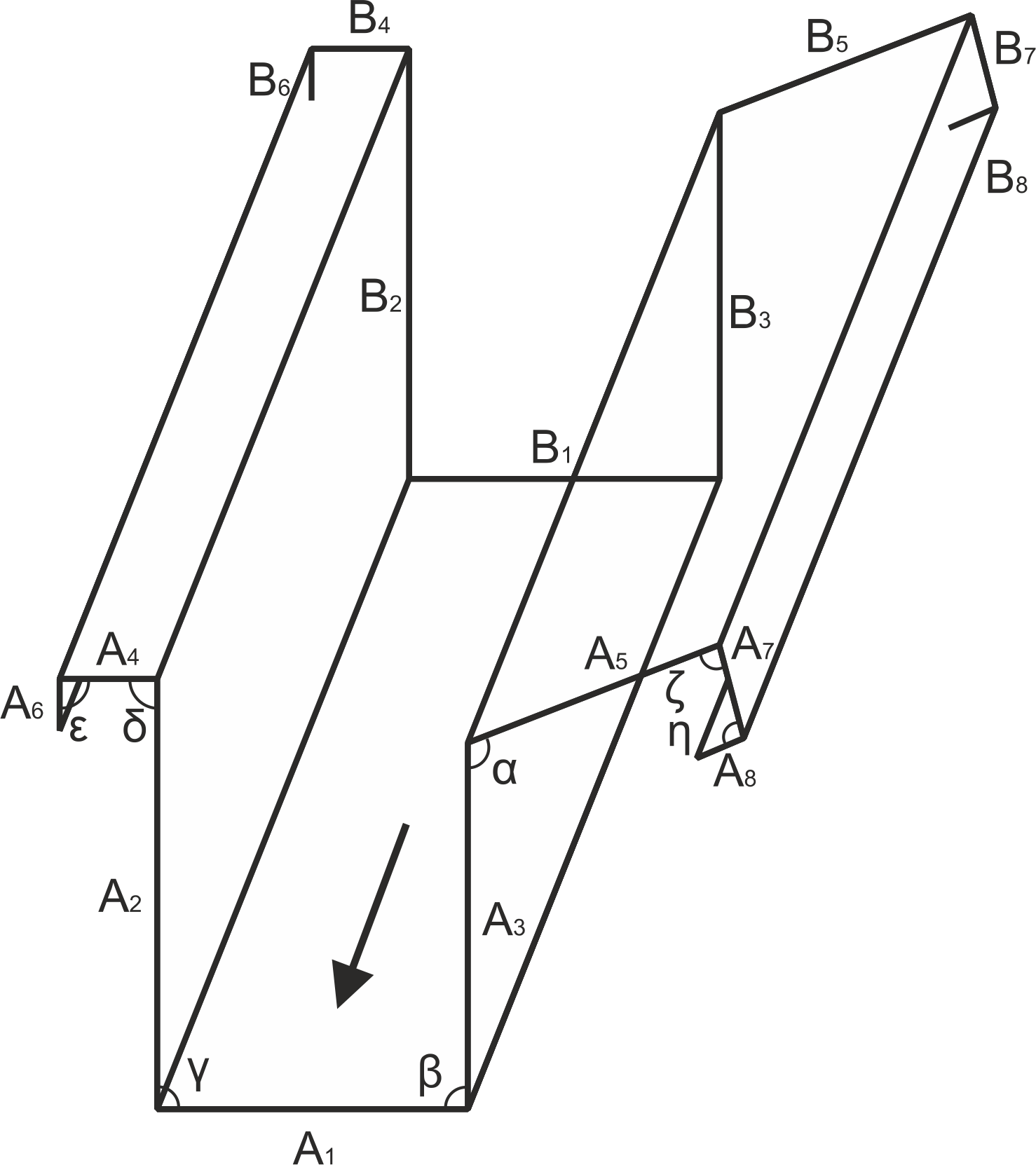

a. Fixed section, according to the special construction needs (figure a & b).

b. Variable section, according to the desirable bottom inclination (0,5-1,5%) and the flow speed (figure c & d).

DOMOLAM gutter points of excellence

1. Length up to 8m in order to limit junctions.

2. Thickness up to 3,00mm for improved rigidity and welding facility.

3. Mode of junction with overlapping or not (face welding).

4. Internal reinforcing formation in order to succeed suspension from the last purlin.

5. External reinforcing formation in order to create socket for the cladding, perfect air-tightness and a horizontal visible edge for more elegant appearance of the building.

6. Easy and precise installation by plain hangers.

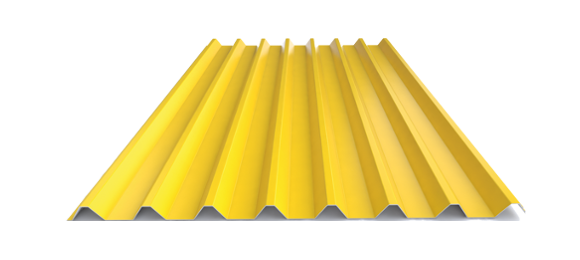

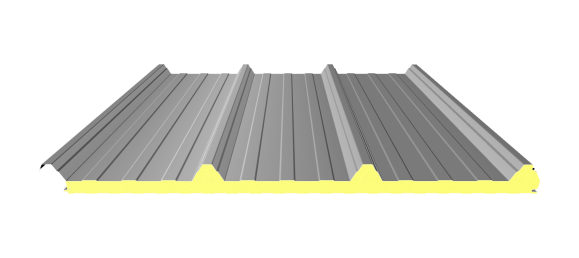

7. They can also be disposed coated with the thermal and sound insulating material ISOLAM in order to avoid vapor condensation and to reduce the energy loss.

They are produced in two types:

a. Fixed section, according to the special construction needs (figure a & b).

b. Variable section, according to the desirable bottom inclination (0,5-1,5%) and the flow speed (figure c & d).

DOMOLAM gutter points of excellence

1. Length up to 8m in order to limit junctions.

2. Thickness up to 3,00mm for improved rigidity and welding facility.

3. Mode of junction with overlapping or not (face welding).

4. Internal reinforcing formation in order to succeed suspension from the last purlin.

5. External reinforcing formation in order to create socket for the cladding, perfect air-tightness and a horizontal visible edge for more elegant appearance of the building.

6. Easy and precise installation by plain hangers.

7. They can also be disposed coated with the thermal and sound insulating material ISOLAM in order to avoid vapor condensation and to reduce the energy loss.