- Characteristics

- Instructions

- Applications

- Certificates

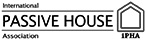

CODE / ΚΩΔ.: PG-C

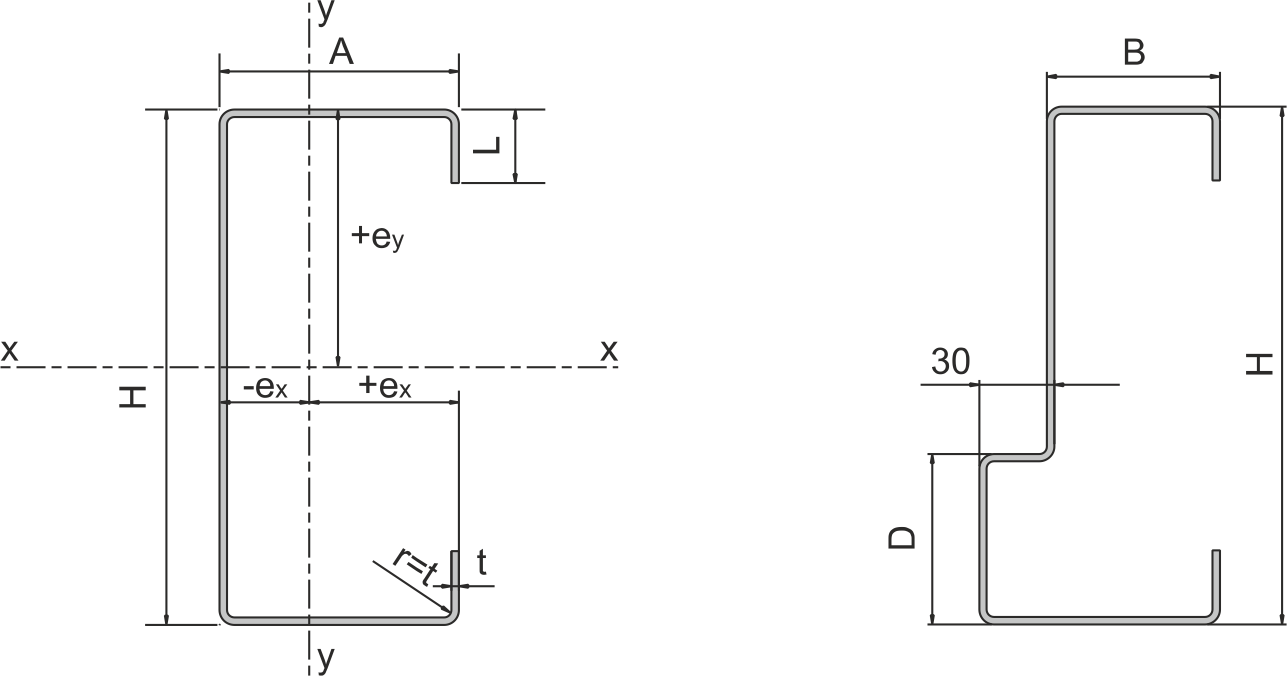

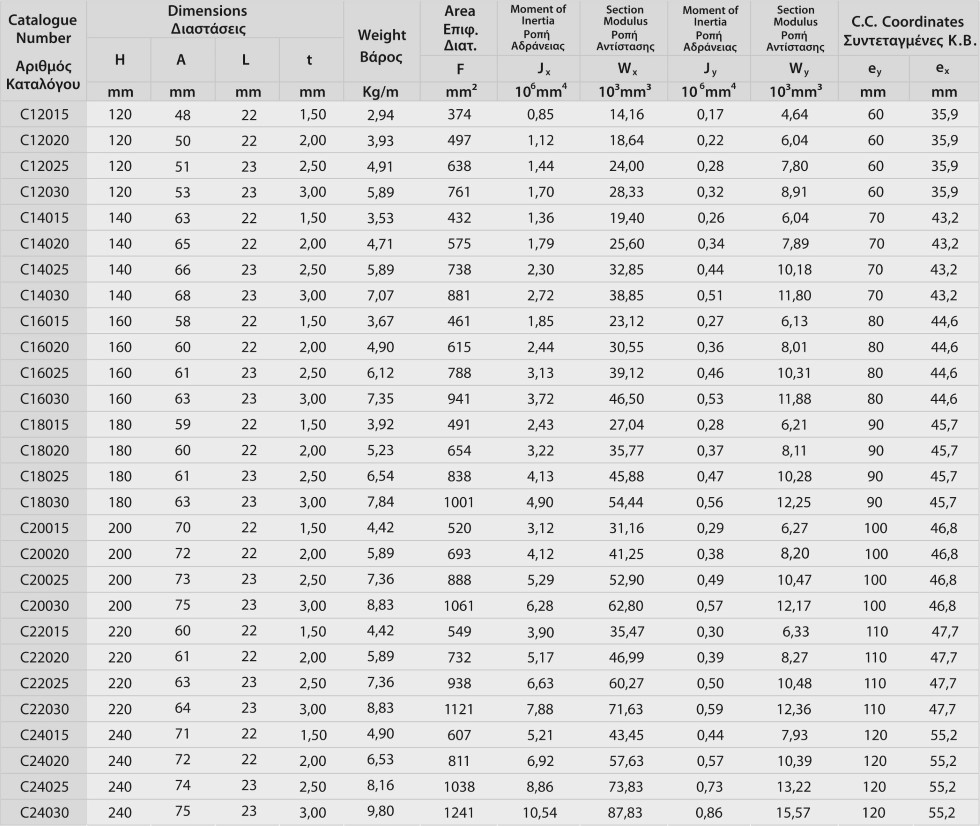

Table of mechanical properties

Unlimited length

Length up to 8 meters

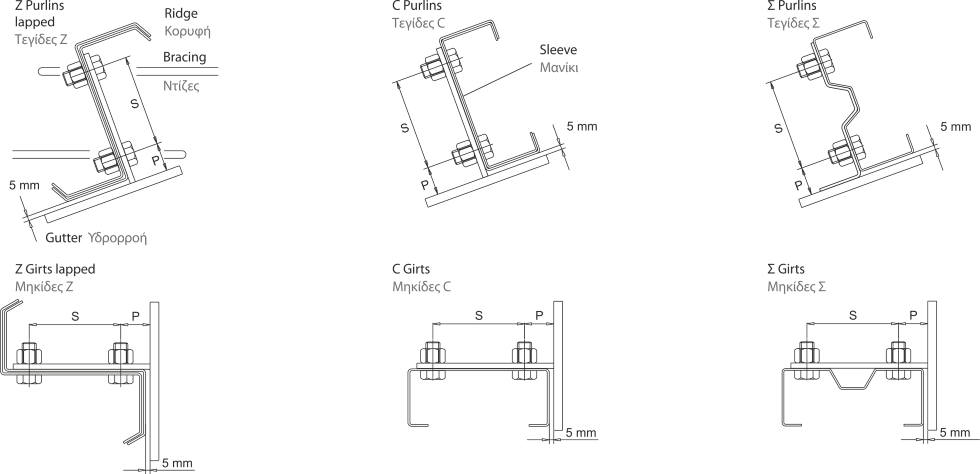

Ζ, C, Σ sections perforation instructions

Unlimited length

Length up to 8 meters

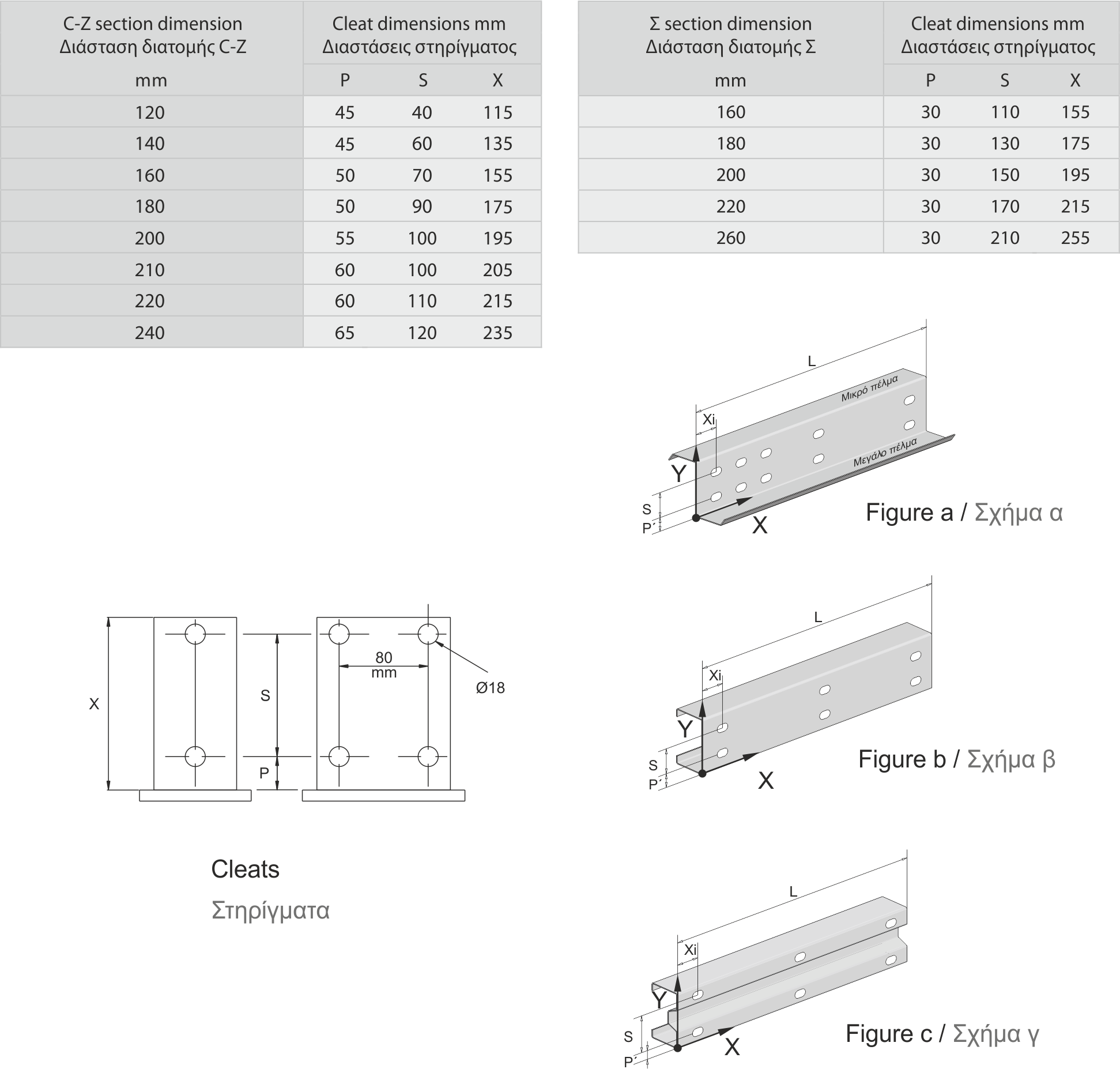

To avoid mistakes, the purlin - girt perforation is recommended to be stated as follows:

Z section purlins: the hole xi positions are defined based on the coordinate system indicated on figure a, initiating from the left purling edge, which "faces" towards the roof ridge. Dimensions S and P' should also be mentioned, where P'=P-5mm.

C or Σ section purlins - girts: the perforations should be stated based on the coordinate system and orientation of figure b and c.

e.g.: Ζ 180 x 2,00mm x L = 6000mm x 10 pieces

P'=40mm, S=100mm, x1=50mm, x2=350mm, x3=650mm, x4=3150mm, x5=5950mm.

The perforations (round Ø16mm or oval 14/22mm and 18/26mm) can be made on the section’s body or the flange, on customized positions and direction. Non standard perforations can be made upon order.

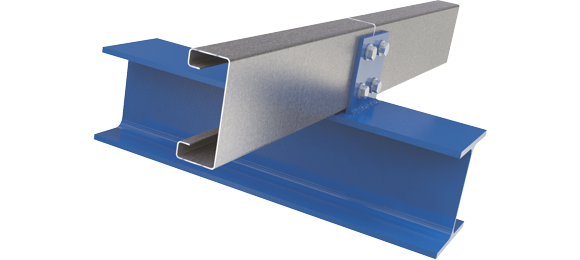

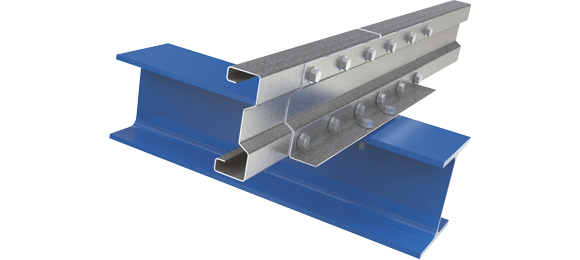

A. By overlapping.

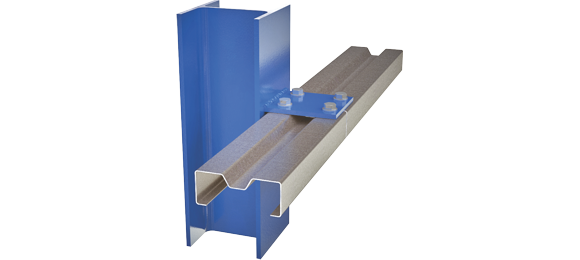

B. Using supporting addition (sleeve).

C. Not continued (butt joint) at the jointing points with the main structure or with direct joints at the points of zero bending moments.

The fully lapped system gives the maximum strength and economy, because it is simulation of continuous beam. The total length of the lap must not be less than 10% of the span or not less than 600mm for 120mm section and 900mm for the 140,

160, 180, 220, and 240mm sections.

Screws & tie rods

M12-8.8 or M16-8.8 bolts depending on with the hole size and the way of assembling and tie rods M12 or M16 with 4 nuts and 4 washers Ø32×2,5mm (spiral length 100mm per side). Tie rods act as braces for the construction reinforcing it against outward

loads. They should be used in the middle of spans so that unbraced length may be limited to 20xH but not more than 3,8m.

PROJECT 19

Galvanized

PROJECT 19

Galvanized

PROJECT 20

Galvanized

PROJECT 20

Galvanized

PROJECT 35

Galvanized

PROJECT 39

Galvanized

PROJECT 33

Galvanized

PROJECT 44

Galvanized

| length (mm) | small | big | weight (kg/m) | weight (kg/m2) | quantity | price per unit (€) | value (€) | Comments |

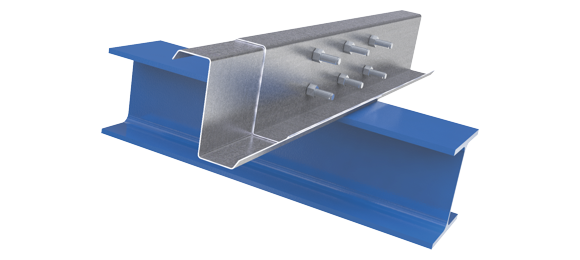

C sections

Technical specifications

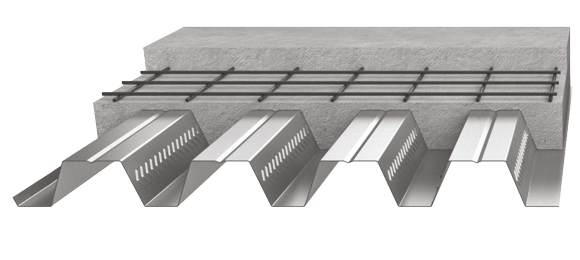

DOMOLAM sections are produced according to EN 1090-1:2009+A1:2011 and have CE marking.

For their production are used DX51D and S320GD hot dip galvanized steel sheets with coating Z275gr/m2, according to the standard EN 10346:2015. They are designed with thickness up to 3,00mm according to EN 1993-1-1:2005 + A1:2014 and they are disposed with round Ø14mm, Ø18mm or oval holes 14x20mm and 18x24mm, on customized positions and direction.