- Characteristics

- Instructions

- Applications

- Certificates

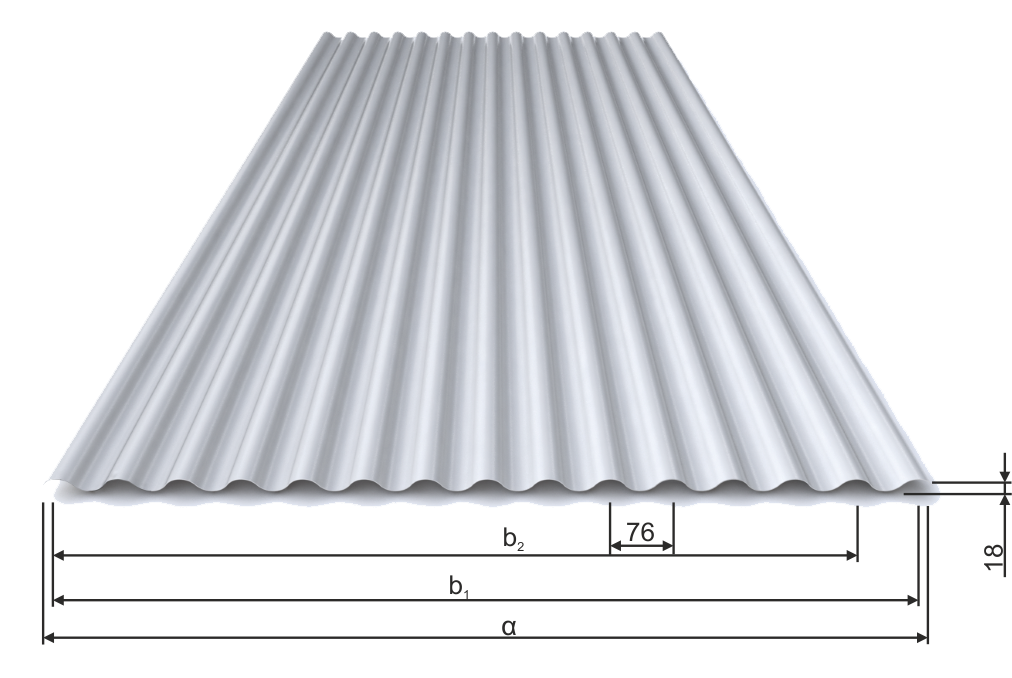

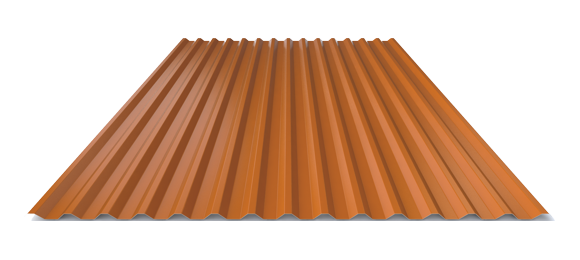

CODE / ΚΩΔ.: S 18/76

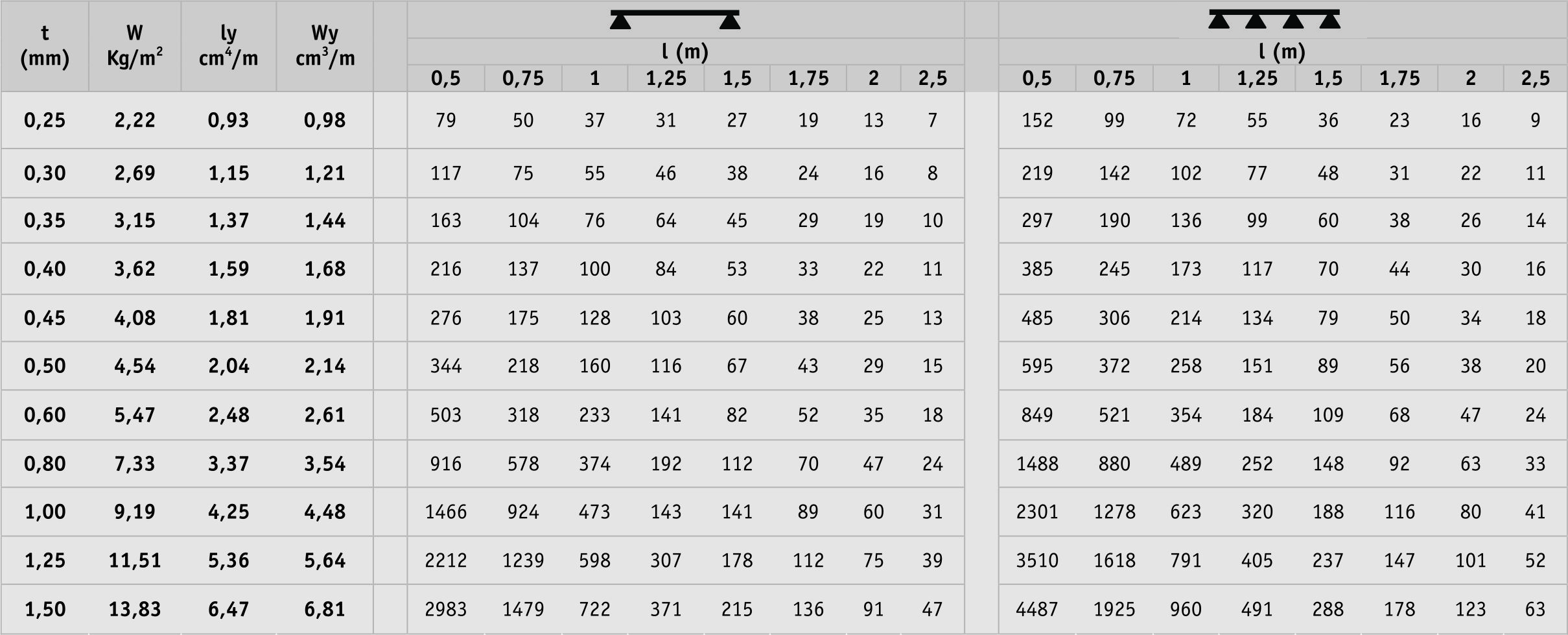

Dimensions - weights table

Table of allowed loads 1) Single span loading 2) 3-span loading

Technical specifications

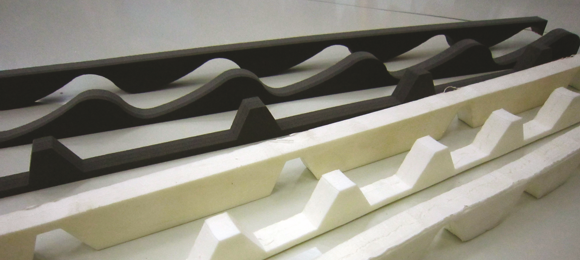

The DOMOLAM metal sheets for roofing and cladding are produced according to the standards EN 14782:2006. The results shown on the resistance tables have been arosen from finite element analysis and experimental verification. Calculations were made with reference to the real thickness, which is lower than the nominal one by the coating thickness (0,04mm for 275gr/m2).

• Seating width b ≥ 50mm.

• Acceptable deflection F ≤ ℓ / 200, E= 2,1 x 106 kg/cm2, uniformly distributed load (Kp/m2).

• Safety factor = 2.

• Yield strength fvb = 280 N/mm2.

The material weight has been subtracted from the loads.

Specification of raw materials

Raw materials complying with high quality and technical standards are used as:

• Raw materials of high quality and technical standards are used, such as:

• Hot-dip zinc coated coils (HDG) Cr+6 free: DX51D+Z, S280GD+Z and S320GD+Z according to the standard EN 10346:2015.

Dimension tolerances according to the standard EN 10143:2006. Coating Ζ275-150.

• Aluminum coated coils: Aluzinc AZ -DX51D+AZ150 (45%Zn, 55%Al) according to the standard ΕΝ 10346:2015.

• Zinc-aluminium-magnesium alloy coated coils: Magnelis ZM -DX51D+ZM90 (93,5%Zn, 3,5%Al, 3%Mg) according to the standard ΕΝ 10346:2015.

• Pre-painted galvanized coils: According to the standard EN 10169:2010 + Α1:2012 with standard polyester 25μ paint in 30 colors.

• Silicon polyester paints, PVDF and other colors upon request.

Transportation

Long packs should be unloaded either with the use of spreader beam or long belts.

Storage

Should be tilted and covered in such a way as to ensure ventilation, in order to avoid vapor condensation and electrochemical corrosion.

Pre-painted sheets should not be dragged.

After the installation, the protective film (if any) should be removed and the roof should be cleaned from cutting and drilling swarfs.

Pre-painted sheets should not be dragged.

After the installation, the protective film (if any) should be removed and the roof should be cleaned from cutting and drilling swarfs.

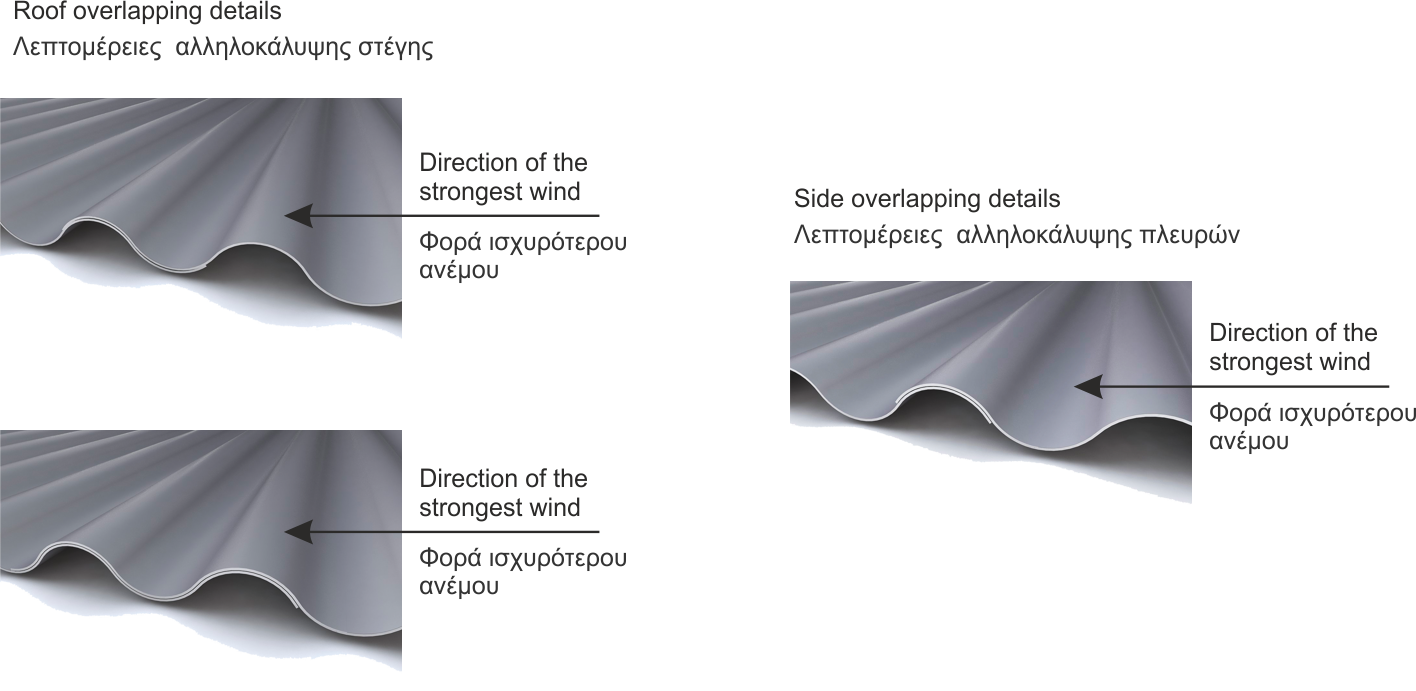

Installation

During fitting, highly concentrated loads between the purlins should be avoided.

It is recommended that at least 2 fasteners should be used on each sheet and purlin, except for the top and bottom part of the sheet, where 3 are necessary.

Fastening should stop when the sheet starts deforming under the screw, to ensure the best aesthetic and static results.

It is recommended that at least 2 fasteners should be used on each sheet and purlin, except for the top and bottom part of the sheet, where 3 are necessary.

Fastening should stop when the sheet starts deforming under the screw, to ensure the best aesthetic and static results.

| length (mm) | small | big | weight (kg/m) | weight (kg/m2) | quantity | price per unit (€) | value (€) | Comments |

Corrugated sheet S 18/76

The traditional choice for the economical covering and cladding of roofs with small distance purlin.

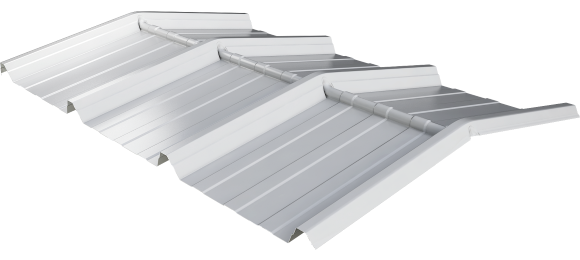

The DOMOLAM metal sheets for roofing and cladding are produced by the continuous cold roll forming process and already include seven different profiles, to fully satisfy all needs, such as the covering of industrial and manufacturing buildings, warehouses and sheds, agricultural and animal breeding facilities, airport and military buildings, sports and shopping centers, garages, etc.

Competitive advantages:

• The wide range of products offers a choice among numerous widths andt hicknesses in order to achieve the most resistant, cost-efficient and aesthetical constructions.

• The option of using wide sheets considerably reduces the overall cost for customers, in terms of material purchase cost (-3%), fastening materials (-10%), and labor cost (-15%).

• Prompt delivery of any desirable dimension and quantity.

The DOMOLAM metal sheets for roofing and cladding are produced by the continuous cold roll forming process and already include seven different profiles, to fully satisfy all needs, such as the covering of industrial and manufacturing buildings, warehouses and sheds, agricultural and animal breeding facilities, airport and military buildings, sports and shopping centers, garages, etc.

Competitive advantages:

• The wide range of products offers a choice among numerous widths andt hicknesses in order to achieve the most resistant, cost-efficient and aesthetical constructions.

• The option of using wide sheets considerably reduces the overall cost for customers, in terms of material purchase cost (-3%), fastening materials (-10%), and labor cost (-15%).

• Prompt delivery of any desirable dimension and quantity.