- Characteristics

- Instructions

- Applications

- Certificates

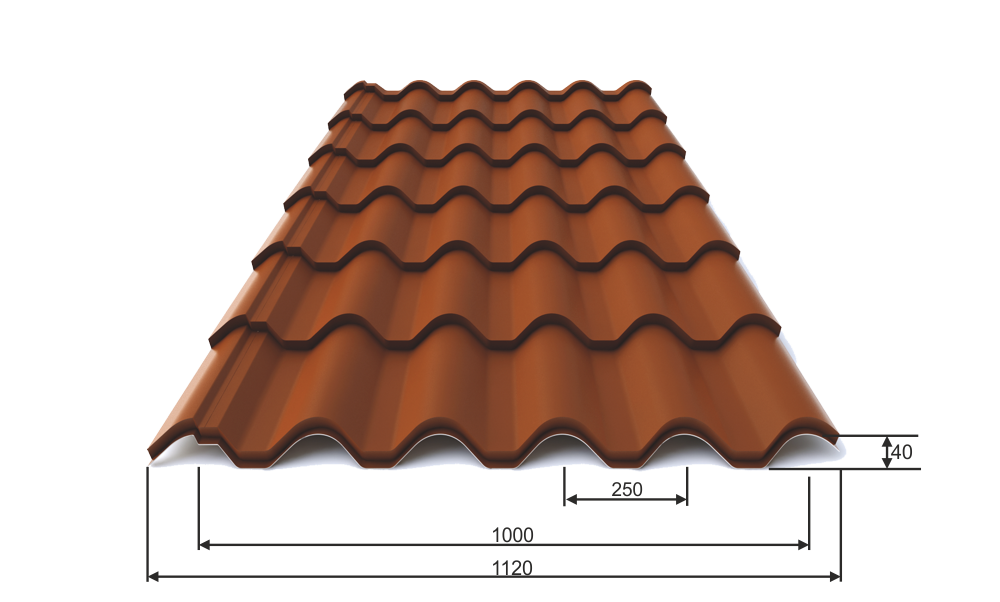

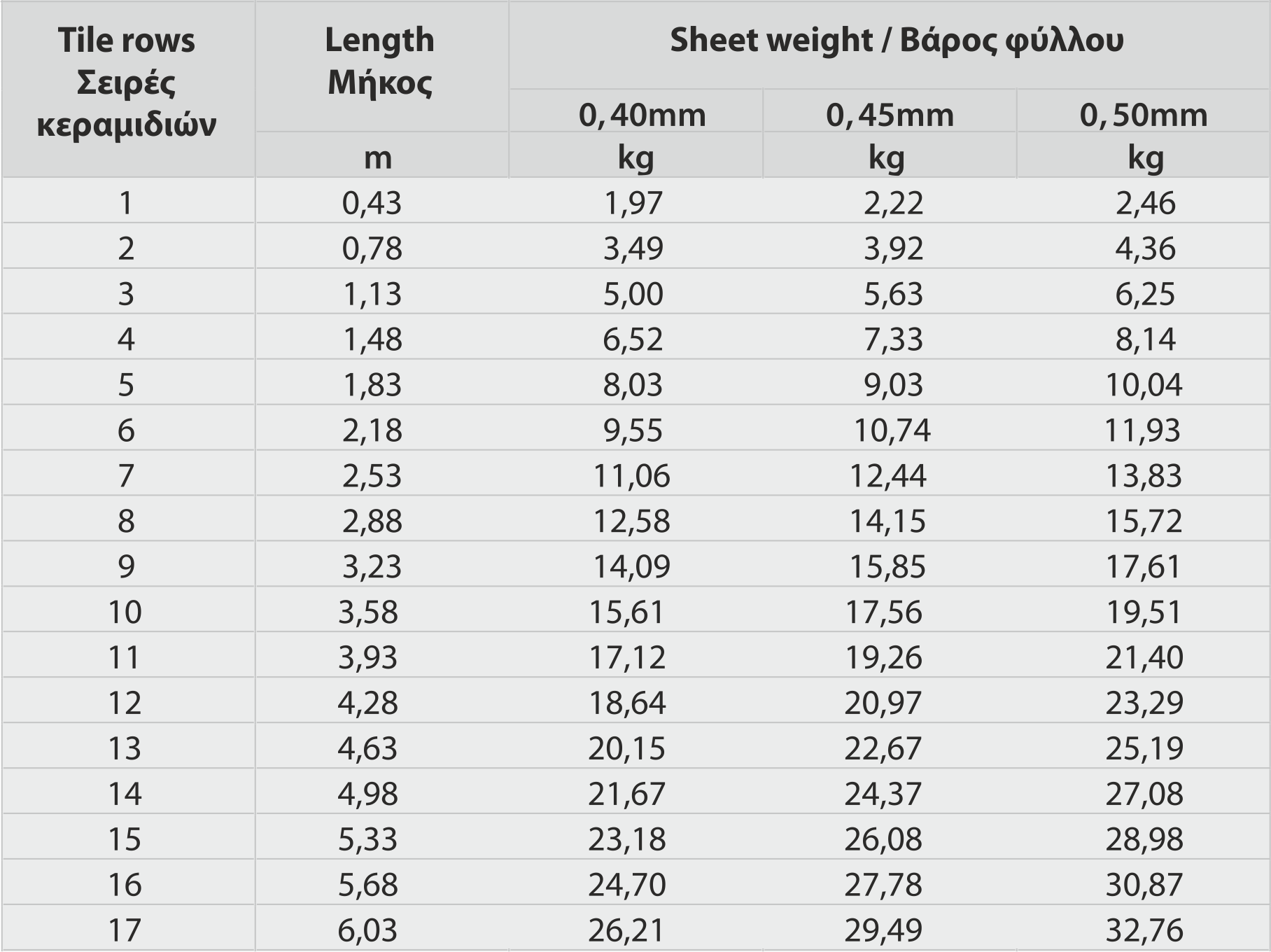

Dimensions - weights table

RemarksThickness: 0,40-0,60mm. Tile length: The standard ceramic tile length (35cm). Different tile lengths upon request. Sheet length: unlimited. A length of up to 6m is recommended in order to facilitate transportation.Tolerances: sheet length ±3mm, sheet width ±5mm. Sheets length overlapping 80mm.

Μodular tiles specifications

• Modular sheets in standard dimensions 780 x 1120mm, in form of 12 "roman" tiles with weight 4,5 kg/piece (for thickness of metal-sheet 0,50 mm) and useful coverage 0.70 m2/piece.

• Revolutionary design for safe and quick placement thanks to the patented hook-up system Z-Lock, where each sheet hides the screws that fix the previous.

• Special configuration at the end of the sheet with perforation for easy placement of screw.

• Three-dimensional cut of sheet’s front edge for practically invisible overlapping.

• Purlin width 80 - 100mm.

Specification of raw materials

Raw materials complying with high quality and technical standards are used as:

• Pre-painted galvanized coils: According to the standard EN 10169:2010 + Α1:2012 with standard polyester 25μ paint in 30 colors.

• Silicon polyester paints, PVDF and other colors upon request.

• Revolutionary design for safe and quick placement thanks to the patented hook-up system Z-Lock, where each sheet hides the screws that fix the previous.

• Special configuration at the end of the sheet with perforation for easy placement of screw.

• Three-dimensional cut of sheet’s front edge for practically invisible overlapping.

• Purlin width 80 - 100mm.

Specification of raw materials

Raw materials complying with high quality and technical standards are used as:

• Pre-painted galvanized coils: According to the standard EN 10169:2010 + Α1:2012 with standard polyester 25μ paint in 30 colors.

• Silicon polyester paints, PVDF and other colors upon request.

Storage

Should be tilted and covered in such a way as to ensure ventilation, in order to avoid vapor condensation and electrochemical corrosion.

Pre-painted sheets should not be dragged.

After the installation, the protective film (if any) should be removed and the roof should be cleaned from cutting and drilling swarfs.

Pre-painted sheets should not be dragged.

After the installation, the protective film (if any) should be removed and the roof should be cleaned from cutting and drilling swarfs.

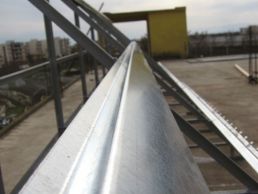

Installation

Installation instructions of modular tiles

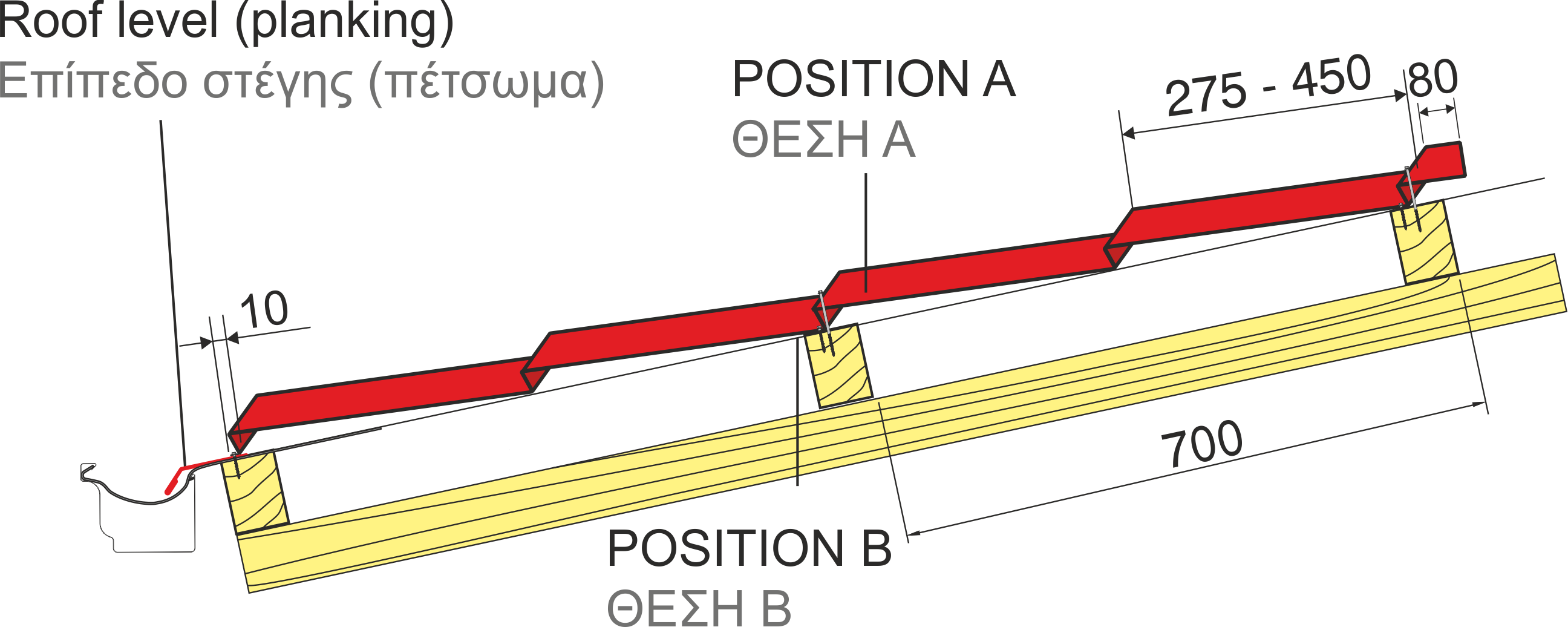

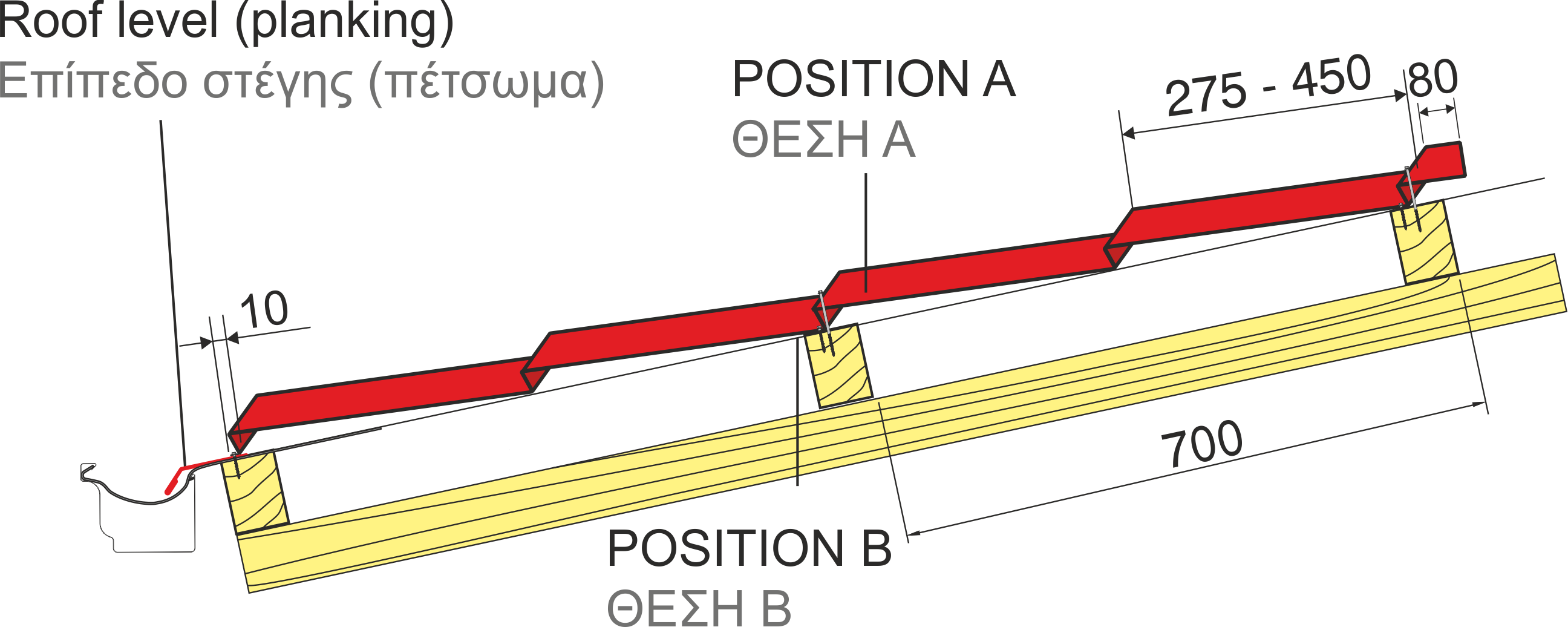

It is recommended that purlins are placed in the front end of the tiles, on the point of contact between the tile and the imaginary level of the roof, as shown in the support detail, and that the screws are placed right after the step at the highest (position A) or

lowest point of the intersection (position B).

lowest point of the intersection (position B).

Installation instructions of modular tiles

• Ensure that the structure is plain.

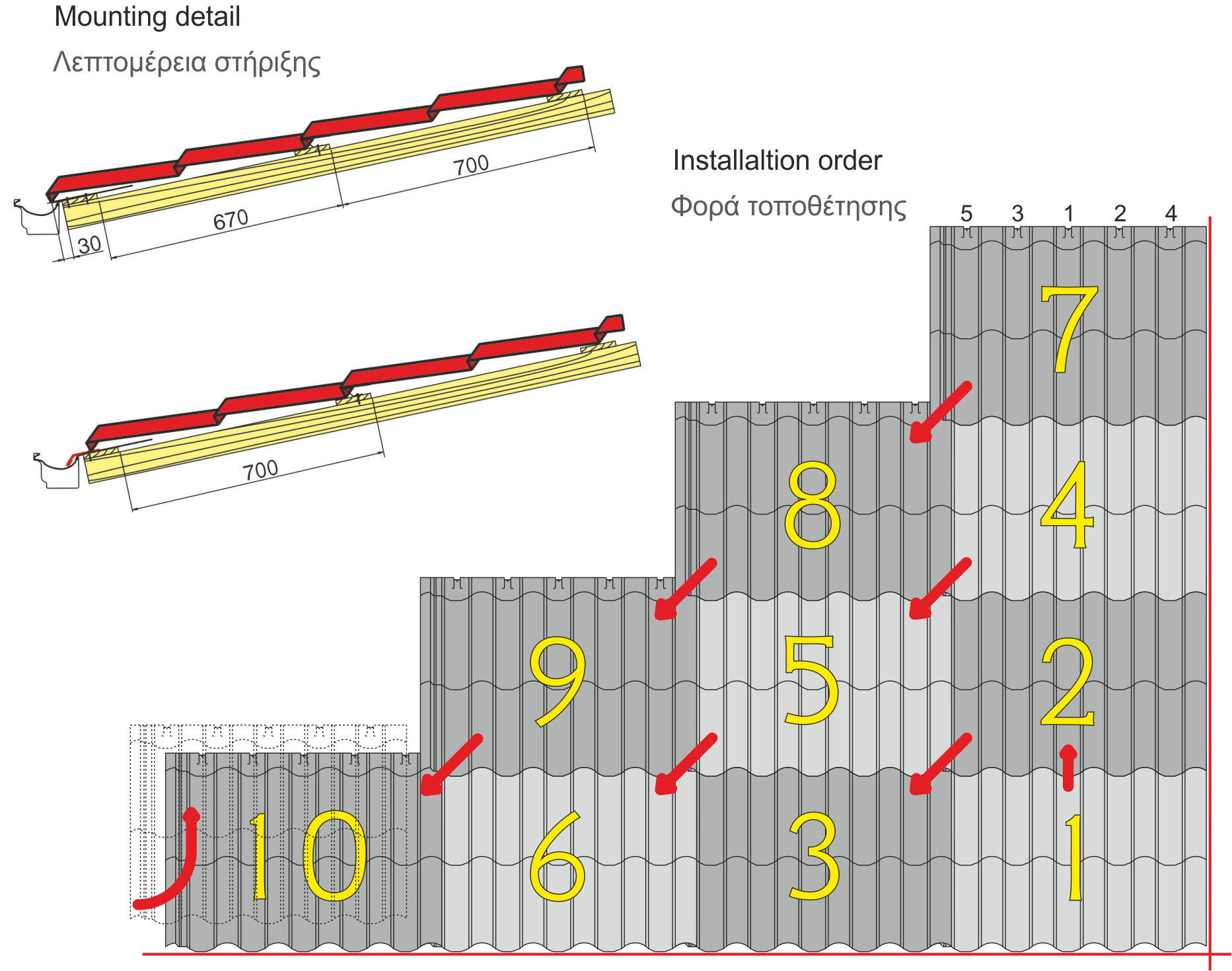

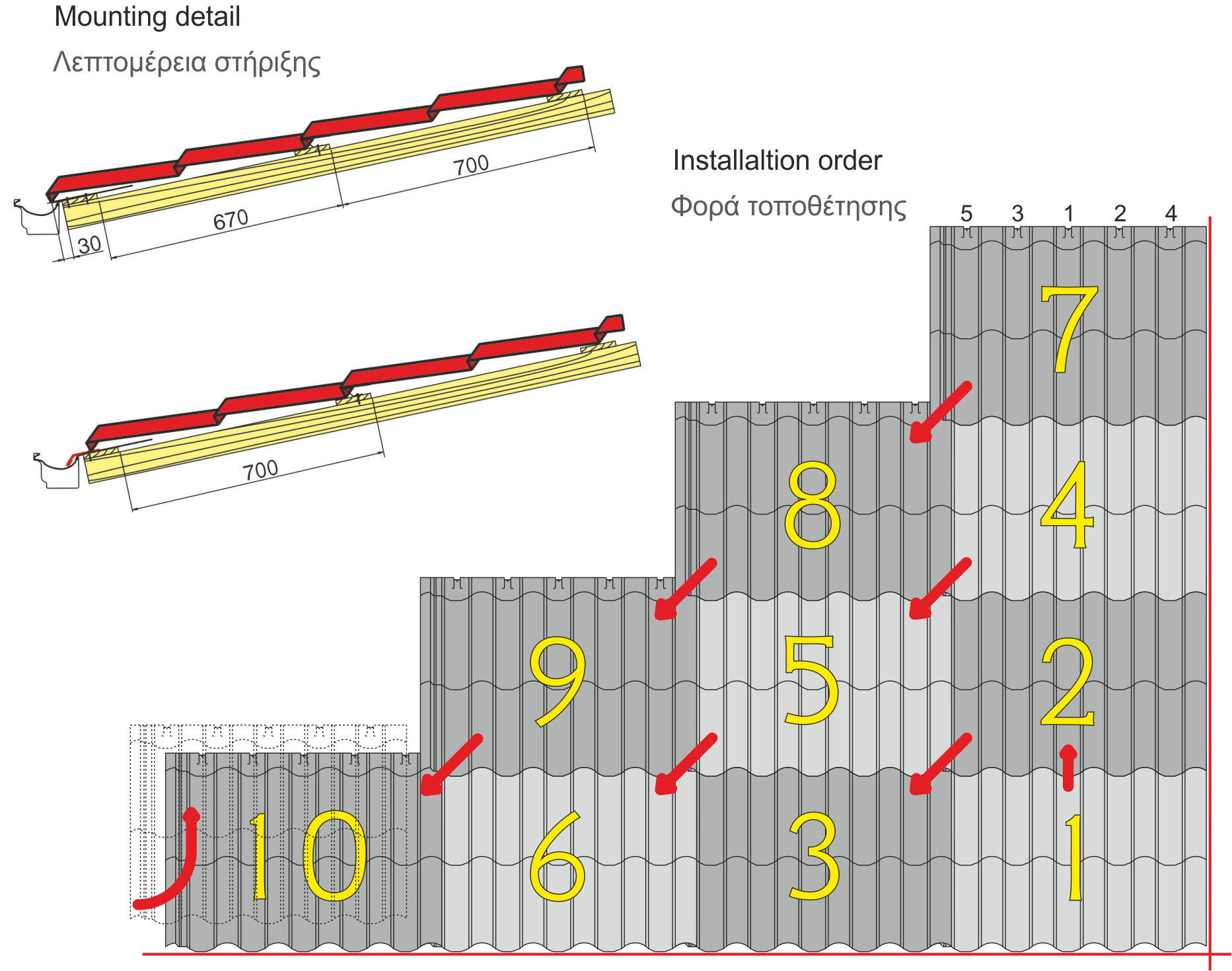

• For hidden fixing and at the beginning of sheets, place the first purlin in a distance of 670mm from the second and fix hook-up clips in the region of gutter 200mm from each other with the help of a string.

• Place the remaining purlins in a distance 2mm smaller than the sheet step, meaning 698mm.

• For visible fixing in the region of gutter use before screwing a sheet protection-corner for purlin, placing it in equal distance with the next, meaning 698mm.

• Place according to the drawing.

• Place each sheet on the previous, so that it follows exactly the step of the previous tile. Be sure that you did not place it out of the vertical and horizontal axis.

• Press hard without deforming each sheet and screw in the prepunched places, securing first the intermediate screws in each sheet that you place.

During fitting, highly concentrated loads between the purlins should be avoided.

It is recommended that at least 2 fasteners should be used on each sheet and purlin, except for the top and bottom part of the sheet, where 3 are necessary.

Fastening should stop when the sheet starts deforming under the screw, to ensure the best aesthetic and static results.

• For hidden fixing and at the beginning of sheets, place the first purlin in a distance of 670mm from the second and fix hook-up clips in the region of gutter 200mm from each other with the help of a string.

• Place the remaining purlins in a distance 2mm smaller than the sheet step, meaning 698mm.

• For visible fixing in the region of gutter use before screwing a sheet protection-corner for purlin, placing it in equal distance with the next, meaning 698mm.

• Place according to the drawing.

• Place each sheet on the previous, so that it follows exactly the step of the previous tile. Be sure that you did not place it out of the vertical and horizontal axis.

• Press hard without deforming each sheet and screw in the prepunched places, securing first the intermediate screws in each sheet that you place.

During fitting, highly concentrated loads between the purlins should be avoided.

It is recommended that at least 2 fasteners should be used on each sheet and purlin, except for the top and bottom part of the sheet, where 3 are necessary.

Fastening should stop when the sheet starts deforming under the screw, to ensure the best aesthetic and static results.

| length (mm) | small | big | weight (kg/m) | weight (kg/m2) | quantity | price per unit (€) | value (€) | Comments |

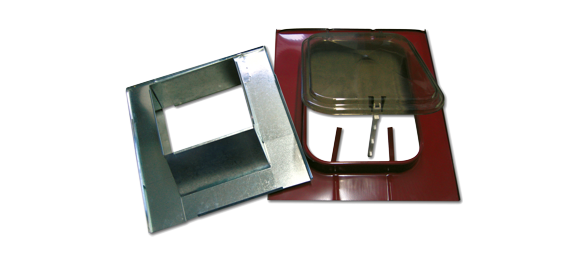

You might also need these products

Roman tiles with hidden fixing TLR 40/200

The “Roman” tiles DOMOLAM with Z-Lock innovation are the most advanced solution for the construction of new roofs and renovation of old. They offer top aesthetical effect ensuring similar geometry to the existing ceramic tiles and they can be produced in two types: in customized length for visible fixing and in standard length 780mm for modular hidden fixing.

“Roman” tiles points of excellence

1. Absolute water-tightness due to the high static height of 40mm and the special form in order to avoid water leaking.

2. Purlin distances up to 70cm, achieving great savings to the load bearing frame.

3. Minimum roof inclination 7%.

4. Possibility for prompt disposal in various colours.

5. Perfect finishing with a complete range of accessories.

6. Negligible cost maintenance.

Modular “Roman” tiles points of excellence

1. Reduction of stock cost due to standard size.

2. Easy and safe product distribution without damages.

3. Easy to order.

4. Possibility of prompt disposal in various colors.

“Roman” tiles points of excellence

1. Absolute water-tightness due to the high static height of 40mm and the special form in order to avoid water leaking.

2. Purlin distances up to 70cm, achieving great savings to the load bearing frame.

3. Minimum roof inclination 7%.

4. Possibility for prompt disposal in various colours.

5. Perfect finishing with a complete range of accessories.

6. Negligible cost maintenance.

Modular “Roman” tiles points of excellence

1. Reduction of stock cost due to standard size.

2. Easy and safe product distribution without damages.

3. Easy to order.

4. Possibility of prompt disposal in various colors.